Top Plastic Extrusion Services Manufacturer in China

By:Admin

As a leading plastic extrusion services manufacturer in China, Foxstar has a strong reputation for delivering superior quality products and exceptional customer service. The company takes pride in its ability to meet the diverse needs of its clients, offering a wide range of services that are tailored to each customer's unique requirements. Whether it's CNC machining, injection molding, sheet metal fabrication, or 3D printing, Foxstar has the expertise and capabilities to deliver the best results.

One of the key strengths of Foxstar is its state-of-the-art facilities and advanced technology. The company has invested heavily in the latest equipment and machinery, enabling it to deliver high-precision products with tight tolerances. This commitment to technology and innovation sets Foxstar apart from other plastic extrusion services manufacturers in China, allowing the company to meet the most demanding requirements of its clients.

In addition to its advanced technology, Foxstar also places a strong emphasis on quality control and assurance. The company has strict quality control measures in place throughout the manufacturing process, ensuring that each product meets the highest standards of excellence. From the selection of raw materials to the final inspection of finished products, Foxstar is dedicated to delivering superior quality at every stage of the production process.

Furthermore, Foxstar is committed to sustainability and environmental responsibility. The company has implemented various initiatives to reduce its carbon footprint and minimize its impact on the environment. This includes the use of eco-friendly materials and processes, as well as the adoption of energy-efficient practices. By prioritizing sustainability, Foxstar is setting a positive example for the industry and demonstrating its dedication to responsible manufacturing.

One of the key advantages of choosing Foxstar as a plastic extrusion services manufacturer in China is the company's ability to offer a comprehensive range of services under one roof. This means that businesses can rely on Foxstar for all of their manufacturing needs, from initial design and prototyping to final production and finishing. With a diverse range of capabilities and expertise, Foxstar is able to streamline the manufacturing process and deliver cost-effective solutions for its clients.

Another factor that sets Foxstar apart from other plastic extrusion services manufacturers in China is its commitment to customer satisfaction. The company places a strong emphasis on building long-term relationships with its clients, striving to understand their unique needs and challenges. By fostering open communication and collaboration, Foxstar is able to deliver customized solutions that meet the specific requirements of each client, ensuring complete satisfaction with the end result.

In conclusion, Foxstar is a leading plastic extrusion services manufacturer in China, offering a wide range of services including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more. With a strong emphasis on precision, efficiency, and customer satisfaction, the company has established itself as a reliable and trusted partner for businesses seeking high-quality manufacturing solutions. By investing in advanced technology, implementing stringent quality control measures, and prioritizing sustainability, Foxstar continues to set the standard for excellence in the industry. Businesses looking for a one-stop solution for their manufacturing needs can turn to Foxstar with confidence, knowing that they will receive exceptional quality and service every step of the way.

Company News & Blog

Top Metal Stamping Manufacturers: Delivering Quality and Precision

Metal Stamping Manufacturers, a leading company in the metal stamping industry, has been making headlines with their innovative and high-quality products. With a history of excellence dating back to [year of establishment], Metal Stamping Manufacturers has established itself as a trusted and reliable source for metal stamping solutions.The company specializes in providing metal stamping services for a wide range of industries, including automotive, aerospace, electronics, and consumer goods. Their state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing them to produce precision-stamped parts with tight tolerances and intricate designs.Metal Stamping Manufacturers takes pride in their ability to offer custom metal stamping solutions to meet the unique needs of their customers. Whether it's a small batch of prototypes or a large-scale production run, the company has the expertise and resources to deliver high-quality stamped parts on time and within budget.One of the key factors that sets Metal Stamping Manufacturers apart from its competitors is their commitment to quality and customer satisfaction. The company follows strict quality control measures at every stage of the manufacturing process to ensure that all stamped parts meet the highest standards of excellence. Additionally, their team of experienced engineers and technicians work closely with customers to understand their specific requirements and provide tailored solutions that exceed expectations.Metal Stamping Manufacturers has also invested heavily in research and development to stay ahead of the curve in the metal stamping industry. They continuously explore new materials, techniques, and processes to improve the efficiency and performance of their products. The company's dedication to innovation has led to the development of cutting-edge metal stamping solutions that have set new benchmarks for quality and precision.In addition to their commitment to quality and innovation, Metal Stamping Manufacturers places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices and measures to minimize their environmental footprint, such as using recyclable materials and reducing waste in their manufacturing processes.Furthermore, Metal Stamping Manufacturers has a proven track record of delivering top-notch customer service. The company's team of dedicated professionals is known for their responsiveness, reliability, and willingness to go the extra mile to meet their customers' needs. This has earned them a loyal and satisfied customer base, including some of the biggest names in the industry.As Metal Stamping Manufacturers continues to expand its reach and capabilities, the company remains focused on maintaining its position as a leader in the metal stamping industry. Their relentless pursuit of excellence and commitment to customer satisfaction has solidified their reputation as a go-to source for high-quality, precision-stamped parts.With their unwavering dedication to quality, innovation, and customer satisfaction, Metal Stamping Manufacturers is poised to continue making significant contributions to the metal stamping industry for years to come. As they look towards the future, the company remains committed to pushing the boundaries of what's possible in metal stamping and setting new standards for excellence in the industry.

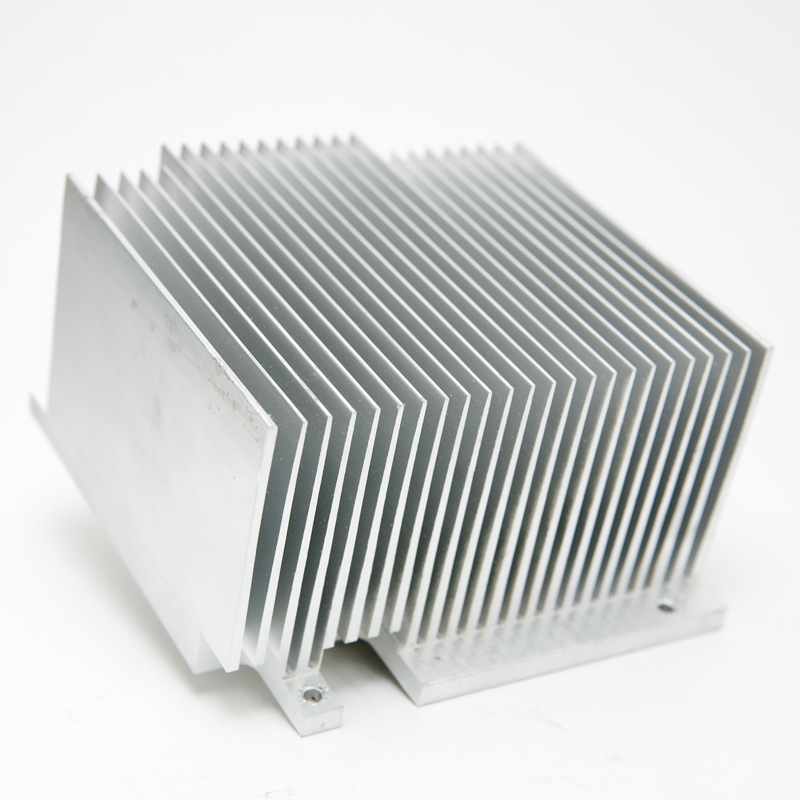

High-Quality Custom Aluminum Extrusion Supplier in China: A Complete Guide

Custom Aluminum Extrusion Supplier in China offers one-stop manufacturing solutions for various industriesAs the global demand for customized aluminum extrusions continues to rise, one company in China is making a name for itself as a leading supplier of custom aluminum extrusions and a variety of manufacturing services. With a focus on delivering superior precision and efficiency on every project, the company, known as Foxstar, is quickly becoming a go-to source for high-quality aluminum extrusions and other manufacturing solutions.Founded with a commitment to excellence, Foxstar has developed a reputation for providing top-notch CNC machining, injection molding, sheet metal fabrication, 3D printing, and more. By offering a wide range of manufacturing processes and materials, the company is able to serve multiple industries with diverse needs and specifications.One of the key strengths of Foxstar is its ability to provide one-stop solutions for manufacturing needs. This means that customers can rely on the company to handle every aspect of the manufacturing process, from design and prototyping to final production and finishing. By offering a comprehensive range of services under one roof, Foxstar streamlines the manufacturing process and ensures that projects are completed with the highest level of precision and efficiency.In addition to its extensive capabilities, Foxstar is known for its commitment to quality and customer satisfaction. The company's team of experienced engineers and technicians works closely with each client to understand their specific requirements and develop customized solutions that meet their needs. Whether it's a complex extrusion project or a simple machining job, Foxstar goes above and beyond to deliver exceptional results that exceed expectations.One of the key offerings of Foxstar is its custom aluminum extrusion services. Aluminum extrusions are widely used in various industries due to their lightweight, durable, and corrosion-resistant properties. With Foxstar's advanced extrusion capabilities, customers can easily create complex, custom-designed aluminum profiles for applications such as architectural framing, automotive components, electronic enclosures, and more.By leveraging state-of-the-art extrusion equipment and a deep understanding of aluminum properties, Foxstar can produce highly precise and intricate extrusions that meet the most demanding requirements. With a variety of finishing options available, including anodizing, powder coating, and polishing, customers can also achieve the desired aesthetic and functional properties for their aluminum extrusions.In addition to aluminum extrusions, Foxstar offers a wide range of other manufacturing services to meet the diverse needs of its customers. From CNC machining for precision parts to injection molding for plastic components, the company has the expertise and equipment to handle a wide range of manufacturing projects. With a strong focus on quality control and attention to detail, Foxstar ensures that each project is completed to the highest standards.Furthermore, Foxstar's commitment to innovation and continuous improvement sets it apart as a leader in the industry. The company consistently invests in the latest technology and equipment to improve its manufacturing processes and expand its capabilities. By staying ahead of industry trends and adopting best practices, Foxstar is able to deliver cutting-edge solutions that meet the evolving needs of its customers.Overall, Foxstar is a trusted partner for companies seeking custom aluminum extrusions and comprehensive manufacturing solutions in China. With its dedication to excellence, extensive capabilities, and customer-centric approach, the company continues to set the standard for quality and reliability in the industry. Whether it's a small prototype or a large-scale production run, Foxstar has the expertise and resources to deliver superior results, making it the supplier of choice for companies across various industries.

High-Quality Small Batch Production Casting Suppliers for Your Manufacturing Needs

Small Batch Production Casting SuppliersSmall batch production is becoming increasingly popular in the manufacturing industry as companies seek to meet the growing demand for customized and specialized products. This trend has led to the rise of small batch production casting suppliers, who provide the necessary expertise and resources to produce high-quality castings in smaller quantities.One such supplier is {}, a leading provider of small batch production casting services. With years of experience in the industry, {} has built a strong reputation for its expertise in producing precision castings for a wide range of industries, including automotive, aerospace, and medical.{} specializes in providing small batch production casting solutions for complex and intricate parts that require a high degree of precision and accuracy. Their state-of-the-art facilities and advanced technologies enable them to produce castings with tight tolerances and intricate geometries, meeting the exact specifications and requirements of their clients.The company's team of skilled engineers and technicians work closely with their clients to understand their specific needs and design custom solutions that meet their unique requirements. Their extensive knowledge and experience in small batch production casting enable them to provide innovative and cost-effective solutions that help their clients optimize their production processes and achieve superior quality products.In addition to their expertise in small batch production casting, {} also offers a wide range of value-added services, including design and engineering support, rapid prototyping, and finishing and assembly services. This comprehensive suite of services allows their clients to streamline their production processes and reduce their time-to-market, while maintaining the highest standards of quality and consistency.{}'s commitment to excellence and customer satisfaction has earned them a loyal clientele and a strong reputation in the industry. Their dedication to delivering superior products and services, combined with their relentless pursuit of innovation and continuous improvement, sets them apart as a trusted partner for small batch production casting solutions.The company's dedication to quality is further reinforced by their compliance with strict quality standards and certifications, ensuring that their products meet the highest industry benchmarks for performance and reliability. This commitment to quality and excellence has earned {} recognition as a leading small batch production casting supplier in the industry.As the demand for small batch production casting continues to grow, {} remains at the forefront of the industry, providing cutting-edge solutions and exceptional customer service to meet the evolving needs of their clients. With a proven track record of success and a commitment to continuous improvement, {} is well-positioned to remain a top choice for small batch production casting services in the years to come.In conclusion, small batch production casting suppliers play a crucial role in enabling companies to meet the growing demand for customized and specialized products. With their expertise and advanced capabilities, suppliers like {} are helping companies across a wide range of industries achieve superior quality and precision in their production processes. As the industry continues to evolve, it is clear that small batch production casting suppliers will continue to be a key partner for companies seeking to differentiate themselves in the market and deliver innovative solutions to their customers.

Custom Plastic Injection Tooling Services: Design, Prototyping, and Manufacturing

Foxstar Technologies Delivers Superior Precision and Efficiency with Plastic Injection ToolingIn today's rapidly evolving manufacturing landscape, the demand for precision and efficiency has never been higher. Companies across various industries are seeking reliable partners to meet their manufacturing needs and deliver high-quality products. Foxstar Technologies is a company that has emerged as a leader in the industry, offering a wide range of manufacturing solutions, including plastic injection tooling, CNC machining, injection molding, sheet metal fabrication, 3D printing, and more.With a strong focus on delivering superior precision and efficiency on every project, Foxstar Technologies has established itself as a trusted partner for companies looking for one-stop manufacturing solutions. The company's commitment to quality and innovation has helped it to serve multiple industries with a variety of materials and finish options, making it a go-to choice for companies looking to bring their products to market.One of the core offerings of Foxstar Technologies is its plastic injection tooling services. This specialized process involves the production of custom molds used in the injection molding process to create plastic parts. With state-of-the-art technology and a team of experienced professionals, Foxstar Technologies is able to provide a wide range of tooling solutions to meet the unique needs of its clients.The company's plastic injection tooling services are known for their precision and efficiency, allowing clients to bring their products to market quickly and cost-effectively. By leveraging advanced manufacturing techniques and cutting-edge technology, Foxstar Technologies is able to deliver high-quality molds that meet the strictest tolerances and quality standards.In addition to plastic injection tooling, Foxstar Technologies offers a comprehensive range of manufacturing solutions to meet the diverse needs of its clients. The company's CNC machining services allow for the precise production of custom parts and components, while its injection molding capabilities enable the cost-effective production of plastic parts in high volumes.Furthermore, Foxstar Technologies provides sheet metal fabrication services, allowing for the production of custom metal parts and enclosures. The company's 3D printing services offer rapid prototyping and low-volume production capabilities, while its finishing options, including painting, plating, and assembly, provide clients with a complete manufacturing solution.With its diverse capabilities and unwavering commitment to quality, Foxstar Technologies has earned a reputation for delivering exceptional value to its clients. The company's one-stop manufacturing solutions have helped its clients to streamline their production processes, reduce lead times, and bring high-quality products to market faster.In addition to its manufacturing capabilities, Foxstar Technologies also offers design and engineering support to help clients bring their concepts to life. The company's team of experienced engineers works closely with clients to develop custom solutions that meet their specific requirements, ensuring that every project is a success.As the manufacturing landscape continues to evolve, Foxstar Technologies remains at the forefront of innovation, continuously investing in new technologies and processes to meet the changing needs of its clients. The company's unwavering commitment to delivering superior precision and efficiency has positioned it as a trusted partner for companies across a wide range of industries.In conclusion, Foxstar Technologies is a company that stands out for its commitment to delivering superior precision and efficiency on every project. With its comprehensive range of manufacturing solutions, including plastic injection tooling, CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, the company offers one-stop solutions for manufacturing needs. By leveraging advanced technology and a team of experienced professionals, Foxstar Technologies has earned a reputation for delivering high-quality products and exceptional value to its clients.

Professional Vacuum Casting Mold Services for High-Quality Prototypes

A leading manufacturer in the field of rapid prototyping and low-volume production, [Company Name] has recently announced the launch of its latest vacuum casting mold service. With over [number] years of experience in the industry, the company has established a reputation for delivering high-quality and cost-effective manufacturing solutions to its clients.Vacuum casting is a versatile and efficient manufacturing process that is widely used in the production of low-volume plastic parts. It involves the use of a silicone mold and a vacuum chamber to create high-quality prototypes and end-use parts. By offering vacuum casting mold services, [Company Name] aims to provide its customers with a quick and reliable method for producing small to medium runs of complex and detailed parts.One of the key advantages of vacuum casting is its ability to replicate the surface finish and mechanical properties of the original master model. This makes it an ideal choice for producing functional prototypes and high-quality end-use parts that closely resemble the final product. Additionally, vacuum casting molds can be produced in a relatively short amount of time, allowing for quick turnaround times and faster time-to-market for new products.[Company Name] understands the importance of delivering exceptional quality to its clients, which is why it uses advanced materials and precise production techniques to ensure the accuracy and consistency of its vacuum casting molds. The company offers a wide range of casting materials, including polyurethane, silicone, and rubber, allowing for the production of parts with varying properties and characteristics.With its state-of-the-art facilities and dedicated team of engineers and technicians, [Company Name] is able to provide comprehensive vacuum casting mold services from design and prototyping to production and post-processing. The company prides itself on its commitment to customer satisfaction and its ability to meet the unique requirements of each project, regardless of size or complexity.In addition to vacuum casting mold services, [Company Name] also offers a full suite of manufacturing solutions, including 3D printing, CNC machining, injection molding, and rapid tooling. This comprehensive range of capabilities allows the company to cater to a wide variety of industries, such as automotive, aerospace, consumer goods, and medical devices."We are thrilled to introduce our new vacuum casting mold service to our clients," said [Spokesperson], [Title] at [Company Name]. "With this addition to our portfolio, we are able to further expand our capabilities and provide our customers with a reliable and cost-effective solution for producing high-quality plastic parts. We look forward to working with our clients to bring their designs to life and help them achieve their manufacturing goals."As [Company Name] continues to grow and expand its services, it remains committed to upholding its reputation as a trusted partner for rapid prototyping and low-volume production. With its focus on innovation, quality, and customer satisfaction, the company is poised to meet the evolving needs of the manufacturing industry and continue to deliver exceptional solutions to its clients.

Types of Molds and Their Rapid Development

Rapid Molds, a leading manufacturing company, is revolutionizing the industry with its advanced technology and innovative approach. The company is known for its high-quality molds and efficient production processes, making it a top choice for businesses in need of custom molds. With state-of-the-art facilities and a team of experienced engineers, Rapid Molds is dedicated to providing top-notch solutions for the manufacturing industry.Founded in 2005, Rapid Molds has quickly made a name for itself in the industry. The company's commitment to excellence and customer satisfaction has earned it a loyal client base and a reputation for reliability. With a focus on continuous improvement and staying ahead of industry trends, Rapid Molds has become a trusted partner for businesses looking for high-quality molds and reliable production processes.One of the key factors that set Rapid Molds apart from its competitors is its use of advanced technology. The company utilizes cutting-edge software and machinery to design and manufacture molds with precision and accuracy. This allows for quicker turnaround times and a higher level of customization, meeting the unique needs of each client. In addition, Rapid Molds is committed to staying current with the latest advancements in mold design and production, ensuring that its clients have access to the most up-to-date solutions available.Another area in which Rapid Molds excels is its commitment to quality control. The company has strict standards in place to ensure that every mold produced meets the highest levels of quality. Additionally, Rapid Molds has implemented rigorous testing and inspection processes to guarantee that each mold performs flawlessly in real-world conditions. This dedication to quality has earned Rapid Molds a reputation for reliability and consistency, making it a top choice for businesses seeking top-notch molds.Rapid Molds also prides itself on its ability to offer a wide range of services to its clients. Whether a business needs a custom mold designed from scratch or requires modifications to an existing mold, Rapid Molds has the expertise and resources to deliver. The company's team of engineers works closely with clients to understand their specific needs and develop tailored solutions that meet or exceed expectations.In addition to its core mold manufacturing services, Rapid Molds also offers consulting and support to help businesses optimize their production processes. The company's engineers are available to provide guidance on mold design, material selection, and production techniques, ensuring that clients can achieve the best results possible. This holistic approach to client support has made Rapid Molds a valuable partner for businesses looking to improve their manufacturing capabilities.As Rapid Molds continues to grow and expand its operations, the company remains committed to its core values of excellence, innovation, and customer satisfaction. With a focus on delivering superior products and services, Rapid Molds is poised to lead the industry for years to come. Businesses in need of top-quality molds and reliable production processes can trust Rapid Molds to deliver the solutions they need to succeed.

Top High Volume Plastic Injection Molding Manufacturer for Your Business

In the world of manufacturing, precision and efficiency are crucial factors in delivering high-quality products. This is especially true in the plastic injection molding industry, where intricate designs and tight tolerances are the norm. Finding a reliable and experienced high-volume plastic injection molding manufacturer can be a challenge, but one company is standing out from the rest – Foxstar.Foxstar is a leading manufacturer in the plastic injection molding industry, delivering superior precision and efficiency on every project. With a wide range of capabilities, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, Foxstar offers one-stop solutions for manufacturing needs across multiple industries.The company's dedication to excellence is evident in its commitment to utilizing the latest technology and equipment to produce high-quality plastic injection molded parts. By investing in state-of-the-art machinery and employing a team of highly skilled engineers and technicians, Foxstar is able to consistently meet the demands of high-volume production while maintaining strict quality control standards.One of the key advantages of working with Foxstar is their ability to work with a variety of materials and finish options. Whether it's producing parts using traditional plastics, engineering-grade resins, or even biodegradable materials, Foxstar has the expertise and capabilities to handle a wide range of materials. Additionally, the company offers a range of finish options, including painting, plating, and texturing, allowing customers to customize the appearance of their parts to meet their specific requirements.Foxstar's dedication to excellence and customer satisfaction has earned them a strong reputation in the industry. By consistently delivering high-quality products and meeting tight production schedules, the company has become a trusted partner for businesses looking for high-volume plastic injection molding solutions.Furthermore, Foxstar's commitment to innovation and continuous improvement is evident in their ability to offer rapid prototyping and low-volume production services using 3D printing technology. This allows customers to quickly test and validate their designs before moving on to high-volume production, saving time and money in the process.With their wide range of capabilities, commitment to quality, and dedication to customer satisfaction, it's no surprise that Foxstar has emerged as one of the best high-volume plastic injection molding manufacturers in the industry. Their ability to deliver superior precision and efficiency on every project, combined with their one-stop manufacturing solutions, makes them a top choice for businesses looking to partner with a reliable and experienced manufacturer.In conclusion, Foxstar is a company that continues to raise the bar for high-volume plastic injection molding manufacturing. Their dedication to excellence, commitment to innovation, and ability to provide one-stop solutions for manufacturing needs make them a valuable partner for businesses across multiple industries. Whether it's producing intricate and complex parts or meeting tight production schedules, Foxstar has proven time and time again that they are the best choice for high-volume plastic injection molding.

Key Considerations for Choosing a Sheet Metal Fabrication Shop

Sheet metal fabrication is a process that involves cutting, bending, and assembling metal to create a wide range of products. From automobile parts to household appliances, sheet metal fabrication plays a crucial role in various industries. One company that has perfected the art of sheet metal fabrication is {Company Name}, a leading fabricator in the industry.With over 20 years of experience, {Company Name} has established itself as a reliable and high-quality sheet metal fabrication shop. Located in the heart of {Location}, the company has earned a reputation for delivering precision-engineered products and solutions to its wide range of clients. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to provide a diverse range of services including laser cutting, welding, powder coating, and more.One of the reasons behind {Company Name}'s success is its commitment to investing in its workforce. The team of skilled technicians and engineers at the company are experts in their field and are dedicated to delivering superior craftsmanship and attention to detail in every project. This commitment to excellence has set {Company Name} apart from its competitors and has allowed them to take on complex and challenging projects across various industries.In recent news, {Company Name} has announced the expansion of its facilities to accommodate the growing demand for its services. The new expansion includes the addition of a larger production floor, new cutting-edge machinery, and an increase in staff to meet the needs of its clients. This expansion comes as a response to the company's continued success and the increasing demand for its services in the region."We are thrilled to announce the expansion of our facilities," said {Spokesperson's Name}, the CEO of {Company Name}. "This expansion is a testament to our commitment to providing our clients with the best possible solutions and our dedication to staying at the forefront of the sheet metal fabrication industry. We are excited about the opportunities this will bring and look forward to continuing to serve our clients with the same level of excellence they have come to expect from us."The expansion of {Company Name}'s facilities will not only allow the company to take on larger and more complex projects but will also create new job opportunities in the community. The company plans to hire additional skilled technicians and engineers to join their team and help meet the increased demand for their services.In addition to the expansion of its facilities, {Company Name} has also announced plans to further invest in research and development to explore new technologies and techniques in the sheet metal fabrication industry. This commitment to innovation will ensure that the company continues to deliver cutting-edge solutions to its clients and maintains its position as a leader in the industry.With its dedication to excellence, commitment to investing in its workforce, and its continued focus on innovation, {Company Name} is poised to continue its success in the sheet metal fabrication industry. The expansion of its facilities and the investment in research and development will further solidify its position as a go-to provider for high-quality sheet metal fabrication solutions.

Top Plastic Extrusion Manufacturer Quotes - Get a Quote Today!

Foxstar Plastic Extrusion Manufacturer Quotes Superior Precision and EfficiencyFoxstar, a leading manufacturing company, is setting new standards in the industry by delivering superior precision and efficiency on every project. With a wide range of manufacturing capabilities, including CNC machining, injection molding, sheet metal fabrication, and 3D printing, Foxstar serves multiple industries with a variety of materials and finish options, providing one-stop solutions for manufacturing needs.As a plastic extrusion manufacturer, Foxstar has built a strong reputation for delivering high-quality products with exceptional precision. The company's commitment to excellence can be seen in its state-of-the-art manufacturing facilities, advanced technologies, and skilled team of engineers and technicians."We are dedicated to providing our customers with the highest level of precision and efficiency," said a spokesperson for Foxstar. "Our advanced manufacturing capabilities allow us to meet the unique needs of each project, ensuring that every product meets the highest standards of quality and performance."Foxstar's plastic extrusion process involves the shaping of raw plastic materials into a continuous profile, which is then cut to the desired length. This process allows for the creation of complex shapes and profiles, making it ideal for a wide range of applications in industries such as automotive, construction, electronics, and more.One of the key advantages of plastic extrusion is its versatility, allowing for the production of a wide range of products, including pipes, tubing, seals, gaskets, and profiles. Foxstar's expertise in plastic extrusion enables the company to offer custom solutions tailored to the specific requirements of each customer, ensuring that every product meets the highest standards of quality and performance.In addition to plastic extrusion, Foxstar also offers a range of other manufacturing services, including CNC machining, injection molding, sheet metal fabrication, and 3D printing. This comprehensive range of capabilities allows Foxstar to provide customers with a one-stop solution for all their manufacturing needs, from prototype development to full-scale production."We take pride in our ability to offer a comprehensive range of manufacturing services, allowing us to meet the diverse needs of our customers," said the spokesperson. "From the initial design phase to the final production, we work closely with our customers to ensure that every project is completed to their exact specifications."Foxstar's commitment to superior precision and efficiency is reflected in its investment in advanced technologies and equipment, as well as its ongoing dedication to continuous improvement. The company's manufacturing facilities are equipped with the latest machinery and tools, allowing for the production of high-quality products with tight tolerances and consistent results."We are constantly investing in the latest technologies and equipment to ensure that we maintain our position as a leader in the industry," said the spokesperson. "By staying ahead of the curve, we are able to offer our customers the highest levels of precision and efficiency, while also reducing lead times and production costs."With its comprehensive range of manufacturing services and commitment to superior precision and efficiency, Foxstar is well-positioned to meet the evolving needs of the industry and continue to deliver high-quality products to its customers. Whether it's plastic extrusion, CNC machining, injection molding, sheet metal fabrication, or 3D printing, Foxstar is dedicated to exceeding customer expectations and setting new standards of excellence in the manufacturing industry.

High-Quality Die Casting Service: What You Need to Know

Die Casting Service has recently announced the expansion of its services, catering to the increasing demand for high-quality die-casting products in the manufacturing industry. With over [number] years of experience in the industry, Die Casting Service has established itself as a reliable and trusted partner for companies looking for precision die-casting solutions.The company specializes in providing custom die-casting services for a wide range of industries, including automotive, aerospace, electronics, and more. Their state-of-the-art facilities and advanced technology allow them to produce complex and intricate die-cast parts with tight tolerances and exceptional surface finishes.Die Casting Service takes pride in its team of highly skilled engineers and technicians who are dedicated to delivering top-notch quality products. They work closely with their clients to understand their specific requirements and provide customized solutions to meet their unique needs. From design and prototyping to production and finishing, the company ensures that every step of the die-casting process is executed with precision and excellence.In addition to their custom die-casting services, Die Casting Service also offers secondary operations such as CNC machining, surface finishing, and assembly to provide a comprehensive solution for their clients. This not only saves time and cost for the clients but also ensures that the final products meet the highest standards of quality and performance.With the expansion of their services, Die Casting Service aims to further strengthen its position as a leading provider of die-casting solutions in the industry. The company has invested in new equipment and technology, as well as increased its production capacity to meet the growing demand for die-cast products."We are excited to announce the expansion of our services to better serve our clients and meet the increasing demand for high-quality die-casting products," said [spokesperson], the CEO of Die Casting Service. "Our commitment to excellence and customer satisfaction remains unwavering, and we are confident that our expanded capabilities will enable us to continue exceeding our clients' expectations."Die Casting Service's dedication to delivering superior die-casting solutions has earned them a solid reputation in the industry. Their clients rely on them for their expertise, reliability, and exceptional quality, and the company is poised to further solidify its position as a trusted partner for die-casting needs."We are proud of the trust and confidence that our clients have placed in us, and we are committed to continuously improving and expanding our services to better serve them," added [spokesperson]. "We look forward to the opportunities that lie ahead and are confident that our expanded capabilities will enable us to take our business to new heights."As the manufacturing industry continues to evolve and demand for high-quality components grows, companies like Die Casting Service are playing a crucial role in providing the necessary solutions. With their expanded services and unwavering commitment to excellence, Die Casting Service is well-positioned to meet the evolving needs of the industry and continue to be a premier provider of die-casting services.