Professional Vacuum Casting Mold Services for High-Quality Prototypes

By:Admin

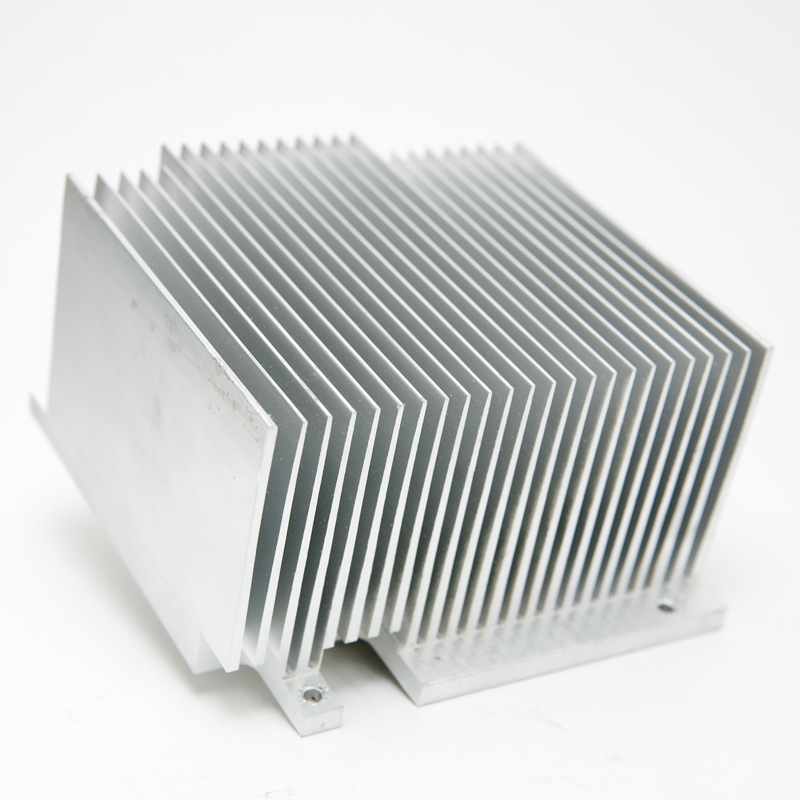

Vacuum casting is a versatile and efficient manufacturing process that is widely used in the production of low-volume plastic parts. It involves the use of a silicone mold and a vacuum chamber to create high-quality prototypes and end-use parts. By offering vacuum casting mold services, [Company Name] aims to provide its customers with a quick and reliable method for producing small to medium runs of complex and detailed parts.

One of the key advantages of vacuum casting is its ability to replicate the surface finish and mechanical properties of the original master model. This makes it an ideal choice for producing functional prototypes and high-quality end-use parts that closely resemble the final product. Additionally, vacuum casting molds can be produced in a relatively short amount of time, allowing for quick turnaround times and faster time-to-market for new products.

[Company Name] understands the importance of delivering exceptional quality to its clients, which is why it uses advanced materials and precise production techniques to ensure the accuracy and consistency of its vacuum casting molds. The company offers a wide range of casting materials, including polyurethane, silicone, and rubber, allowing for the production of parts with varying properties and characteristics.

With its state-of-the-art facilities and dedicated team of engineers and technicians, [Company Name] is able to provide comprehensive vacuum casting mold services from design and prototyping to production and post-processing. The company prides itself on its commitment to customer satisfaction and its ability to meet the unique requirements of each project, regardless of size or complexity.

In addition to vacuum casting mold services, [Company Name] also offers a full suite of manufacturing solutions, including 3D printing, CNC machining, injection molding, and rapid tooling. This comprehensive range of capabilities allows the company to cater to a wide variety of industries, such as automotive, aerospace, consumer goods, and medical devices.

"We are thrilled to introduce our new vacuum casting mold service to our clients," said [Spokesperson], [Title] at [Company Name]. "With this addition to our portfolio, we are able to further expand our capabilities and provide our customers with a reliable and cost-effective solution for producing high-quality plastic parts. We look forward to working with our clients to bring their designs to life and help them achieve their manufacturing goals."

As [Company Name] continues to grow and expand its services, it remains committed to upholding its reputation as a trusted partner for rapid prototyping and low-volume production. With its focus on innovation, quality, and customer satisfaction, the company is poised to meet the evolving needs of the manufacturing industry and continue to deliver exceptional solutions to its clients.

Company News & Blog

Top-notch 3D printing: Why it is the future of manufacturing

The world of manufacturing and production is rapidly evolving with the emergence of high-quality 3D printing technology. This groundbreaking innovation has the potential to revolutionize the way products are designed, developed, and produced. One company that is at the forefront of this technological advancement is {}.{} is a leading provider of innovative 3D printing solutions that are designed to meet the demands of a wide range of industries. With a focus on delivering high-quality, reliable, and cost-effective printing solutions, {} has become a trusted partner for businesses looking to take advantage of the benefits offered by 3D printing.The team at {} is committed to pushing the boundaries of what is possible with 3D printing. By leveraging the latest advancements in technology and materials, they are able to produce parts and products that meet the highest standards of quality and precision. Whether it's creating prototypes, custom components, or end-use parts, {} has the expertise and technology to bring ideas to life in a way that was previously not possible.One of the key advantages of {}'s 3D printing solutions is the ability to produce complex geometries and intricate designs with ease. Traditional manufacturing methods often struggle to achieve the level of detail and precision that is possible with 3D printing. This opens up new opportunities for designers and engineers to create innovative products that were once out of reach.In addition to the design flexibility offered by 3D printing, {} is also able to deliver fast turnaround times. This means that businesses can bring their products to market more quickly, reducing lead times and accelerating the pace of innovation. With the ability to produce parts on-demand, companies can also reduce inventory costs and minimize waste, making their operations more efficient and sustainable.Another important aspect of {}'s 3D printing solutions is the ability to work with a wide range of materials. Whether it's plastics, metals, ceramics, or composites, {} has the expertise to produce parts in the most suitable material for the application. This ensures that their customers can find the right balance of strength, durability, and performance for their specific needs.The application of {}'s 3D printing technology is vast and varied. Industries such as aerospace, automotive, healthcare, consumer goods, and more can all benefit from the capabilities offered by 3D printing. Whether it's creating lightweight components for aircraft, custom medical implants, or intricate consumer products, {} has the expertise and capability to meet the demands of these diverse markets.Looking ahead, {} is poised to continue leading the way in the world of 3D printing. With ongoing investments in research and development, as well as a commitment to staying at the forefront of technological advancements, {} is well-positioned to continue delivering cutting-edge solutions to their customers. As the demand for high-quality 3D printing continues to grow, {} is ready to meet the needs of businesses looking to take advantage of this revolutionary technology.In conclusion, high-quality 3D printing is ushering in a new era of manufacturing and production. {} is at the forefront of this technological revolution, offering innovative solutions that are designed to meet the demands of a wide range of industries. With their expertise, technology, and commitment to excellence, {} is helping businesses bring their ideas to life in ways that were previously not possible. As the potential of 3D printing continues to expand, {} stands ready to lead the way into this exciting future.

High-quality Small Batch Production Casting Quotes for OEM Manufacturing

With the increasing demand for custom and small batch production, the need for reliable OEM small batch production casting services has also seen a significant uptick. Businesses are looking for manufacturing partners that can provide high-quality and cost-effective solutions for producing small quantities of custom parts and components. In response to this demand, [company name] has emerged as a leading provider of OEM small batch production casting services, offering a range of casting solutions to meet the diverse needs of businesses across various industries.[Company name] is a well-established manufacturing company with a strong reputation for delivering precision-engineered components and parts through advanced casting processes. With a focus on meeting the needs of small and medium-sized businesses, the company has positioned itself as a go-to partner for OEM small batch production casting. By leveraging cutting-edge technology and a skilled team of engineers and technicians, [company name] offers a wide variety of casting processes, including investment casting, sand casting, die casting, and more. This allows businesses to access a full suite of casting options to suit their specific requirements.One of the key advantages of partnering with [company name] for OEM small batch production casting is the company's emphasis on quality and precision. The company has invested in state-of-the-art equipment and modern facilities to ensure that each casting project meets the highest standards of quality and accuracy. With a commitment to continuous improvement and innovation, [company name] is able to deliver consistently high-quality casting solutions that meet the exact specifications of their clients.In addition to its focus on quality, [company name] also understands the importance of cost-effectiveness in small batch production. The company's streamlined manufacturing processes and efficient production methods allow them to offer competitive pricing for small quantity orders, without sacrificing on quality. This makes [company name] an attractive option for businesses looking to produce custom components or parts in smaller quantities, without breaking the bank.Furthermore, [company name] places a strong emphasis on customer satisfaction and service excellence. The company's team of experienced professionals works closely with clients to understand their unique requirements and provide personalized guidance throughout the entire casting process. From design and prototyping to production and delivery, [company name] is dedicated to ensuring that every client receives the attention and support they need to achieve their manufacturing goals.With its comprehensive range of casting processes, commitment to quality, cost-effective solutions, and customer-centric approach, [company name] has established itself as a trusted partner for OEM small batch production casting. Businesses can rely on the company to deliver high-quality, precision-casted components and parts that meet their exact specifications, while also benefiting from competitive pricing and exceptional customer service.In today's dynamic and competitive manufacturing landscape, having a reliable and capable partner for OEM small batch production casting is an invaluable asset for businesses. With its proven track record and commitment to excellence, [company name] continues to be a leading choice for businesses seeking high-quality, cost-effective casting solutions for their small batch production needs. As the demand for custom and small batch production continues to grow, [company name] is well-positioned to meet the evolving needs of businesses and deliver top-tier casting services that drive success and satisfaction.

Top Metal Stamping Manufacturers: Delivering Quality and Precision

Metal Stamping Manufacturers, a leading company in the metal stamping industry, has been making headlines with their innovative and high-quality products. With a history of excellence dating back to [year of establishment], Metal Stamping Manufacturers has established itself as a trusted and reliable source for metal stamping solutions.The company specializes in providing metal stamping services for a wide range of industries, including automotive, aerospace, electronics, and consumer goods. Their state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing them to produce precision-stamped parts with tight tolerances and intricate designs.Metal Stamping Manufacturers takes pride in their ability to offer custom metal stamping solutions to meet the unique needs of their customers. Whether it's a small batch of prototypes or a large-scale production run, the company has the expertise and resources to deliver high-quality stamped parts on time and within budget.One of the key factors that sets Metal Stamping Manufacturers apart from its competitors is their commitment to quality and customer satisfaction. The company follows strict quality control measures at every stage of the manufacturing process to ensure that all stamped parts meet the highest standards of excellence. Additionally, their team of experienced engineers and technicians work closely with customers to understand their specific requirements and provide tailored solutions that exceed expectations.Metal Stamping Manufacturers has also invested heavily in research and development to stay ahead of the curve in the metal stamping industry. They continuously explore new materials, techniques, and processes to improve the efficiency and performance of their products. The company's dedication to innovation has led to the development of cutting-edge metal stamping solutions that have set new benchmarks for quality and precision.In addition to their commitment to quality and innovation, Metal Stamping Manufacturers places a strong emphasis on sustainability and environmental responsibility. The company has implemented eco-friendly practices and measures to minimize their environmental footprint, such as using recyclable materials and reducing waste in their manufacturing processes.Furthermore, Metal Stamping Manufacturers has a proven track record of delivering top-notch customer service. The company's team of dedicated professionals is known for their responsiveness, reliability, and willingness to go the extra mile to meet their customers' needs. This has earned them a loyal and satisfied customer base, including some of the biggest names in the industry.As Metal Stamping Manufacturers continues to expand its reach and capabilities, the company remains focused on maintaining its position as a leader in the metal stamping industry. Their relentless pursuit of excellence and commitment to customer satisfaction has solidified their reputation as a go-to source for high-quality, precision-stamped parts.With their unwavering dedication to quality, innovation, and customer satisfaction, Metal Stamping Manufacturers is poised to continue making significant contributions to the metal stamping industry for years to come. As they look towards the future, the company remains committed to pushing the boundaries of what's possible in metal stamping and setting new standards for excellence in the industry.

How to Print a 3D Model: A Step-by-Step Guide

Innovative Company Introduces Cutting-Edge 3D Printing TechnologyIn a world where technology continues to advance at an exponential rate, the introduction of 3D printing has revolutionized the way we manufacture and create products. One company at the forefront of this technological advancement is pushing the boundaries of what is possible with their state-of-the-art 3D printing technology.This forward-thinking company has recently unveiled a groundbreaking 3D printing process that has the potential to revolutionize the way products are made. Their cutting-edge technology allows for the creation of highly complex and intricate 3D models with unparalleled precision and detail. This advancement in 3D printing technology has the potential to disrupt traditional manufacturing processes and pave the way for a new era of innovation and creativity.The company's proprietary 3D printing technology is capable of producing highly detailed and accurate models with a level of precision that was previously thought to be impossible. This breakthrough in 3D printing has the potential to transform a wide range of industries, from aerospace and automotive to healthcare and consumer goods.One of the key advantages of this advanced 3D printing technology is its ability to create complex and customizable products with incredible speed and efficiency. This means that companies can now rapidly prototype and produce high-quality products with minimal lead times, significantly reducing time-to-market and overall production costs.The potential applications for this cutting-edge 3D printing technology are virtually limitless. From creating intricate architectural models to producing custom medical implants, the possibilities are endless. The company's innovative approach to 3D printing has the potential to transform the way we think about design and manufacturing, opening up new opportunities for creativity and innovation.In addition to its advanced 3D printing technology, the company has also established itself as a leader in the industry through its dedication to sustainability and environmental responsibility. By using biodegradable and recyclable materials in its 3D printing process, the company is committed to reducing its environmental impact and promoting sustainable manufacturing practices.Furthermore, the company's focus on research and development has led to continuous advancements in 3D printing technology, ensuring that it remains at the forefront of innovation. With a team of talented engineers and designers, the company is constantly pushing the boundaries of what is possible with 3D printing, developing new techniques and materials that further enhance the capabilities of their technology.As the demand for highly customized and intricately designed products continues to grow, the company's advanced 3D printing technology is poised to play a pivotal role in shaping the future of manufacturing. With its commitment to innovation, sustainability, and excellence, this company is well positioned to lead the way in the rapidly evolving world of 3D printing.In conclusion, the introduction of this cutting-edge 3D printing technology has the potential to transform the manufacturing industry and revolutionize the way products are made. With its unparalleled precision, speed, and sustainability, this innovative company is paving the way for a new era of creativity and possibility. As 3D printing technology continues to advance, the company is poised to remain at the forefront of innovation, driving meaningful change and shaping the future of manufacturing.

High-Quality Die Casting Service: What You Need to Know

Die Casting Service has recently announced the expansion of its services, catering to the increasing demand for high-quality die-casting products in the manufacturing industry. With over [number] years of experience in the industry, Die Casting Service has established itself as a reliable and trusted partner for companies looking for precision die-casting solutions.The company specializes in providing custom die-casting services for a wide range of industries, including automotive, aerospace, electronics, and more. Their state-of-the-art facilities and advanced technology allow them to produce complex and intricate die-cast parts with tight tolerances and exceptional surface finishes.Die Casting Service takes pride in its team of highly skilled engineers and technicians who are dedicated to delivering top-notch quality products. They work closely with their clients to understand their specific requirements and provide customized solutions to meet their unique needs. From design and prototyping to production and finishing, the company ensures that every step of the die-casting process is executed with precision and excellence.In addition to their custom die-casting services, Die Casting Service also offers secondary operations such as CNC machining, surface finishing, and assembly to provide a comprehensive solution for their clients. This not only saves time and cost for the clients but also ensures that the final products meet the highest standards of quality and performance.With the expansion of their services, Die Casting Service aims to further strengthen its position as a leading provider of die-casting solutions in the industry. The company has invested in new equipment and technology, as well as increased its production capacity to meet the growing demand for die-cast products."We are excited to announce the expansion of our services to better serve our clients and meet the increasing demand for high-quality die-casting products," said [spokesperson], the CEO of Die Casting Service. "Our commitment to excellence and customer satisfaction remains unwavering, and we are confident that our expanded capabilities will enable us to continue exceeding our clients' expectations."Die Casting Service's dedication to delivering superior die-casting solutions has earned them a solid reputation in the industry. Their clients rely on them for their expertise, reliability, and exceptional quality, and the company is poised to further solidify its position as a trusted partner for die-casting needs."We are proud of the trust and confidence that our clients have placed in us, and we are committed to continuously improving and expanding our services to better serve them," added [spokesperson]. "We look forward to the opportunities that lie ahead and are confident that our expanded capabilities will enable us to take our business to new heights."As the manufacturing industry continues to evolve and demand for high-quality components grows, companies like Die Casting Service are playing a crucial role in providing the necessary solutions. With their expanded services and unwavering commitment to excellence, Die Casting Service is well-positioned to meet the evolving needs of the industry and continue to be a premier provider of die-casting services.

Types of Molds and Their Rapid Development

Rapid Molds, a leading manufacturing company, is revolutionizing the industry with its advanced technology and innovative approach. The company is known for its high-quality molds and efficient production processes, making it a top choice for businesses in need of custom molds. With state-of-the-art facilities and a team of experienced engineers, Rapid Molds is dedicated to providing top-notch solutions for the manufacturing industry.Founded in 2005, Rapid Molds has quickly made a name for itself in the industry. The company's commitment to excellence and customer satisfaction has earned it a loyal client base and a reputation for reliability. With a focus on continuous improvement and staying ahead of industry trends, Rapid Molds has become a trusted partner for businesses looking for high-quality molds and reliable production processes.One of the key factors that set Rapid Molds apart from its competitors is its use of advanced technology. The company utilizes cutting-edge software and machinery to design and manufacture molds with precision and accuracy. This allows for quicker turnaround times and a higher level of customization, meeting the unique needs of each client. In addition, Rapid Molds is committed to staying current with the latest advancements in mold design and production, ensuring that its clients have access to the most up-to-date solutions available.Another area in which Rapid Molds excels is its commitment to quality control. The company has strict standards in place to ensure that every mold produced meets the highest levels of quality. Additionally, Rapid Molds has implemented rigorous testing and inspection processes to guarantee that each mold performs flawlessly in real-world conditions. This dedication to quality has earned Rapid Molds a reputation for reliability and consistency, making it a top choice for businesses seeking top-notch molds.Rapid Molds also prides itself on its ability to offer a wide range of services to its clients. Whether a business needs a custom mold designed from scratch or requires modifications to an existing mold, Rapid Molds has the expertise and resources to deliver. The company's team of engineers works closely with clients to understand their specific needs and develop tailored solutions that meet or exceed expectations.In addition to its core mold manufacturing services, Rapid Molds also offers consulting and support to help businesses optimize their production processes. The company's engineers are available to provide guidance on mold design, material selection, and production techniques, ensuring that clients can achieve the best results possible. This holistic approach to client support has made Rapid Molds a valuable partner for businesses looking to improve their manufacturing capabilities.As Rapid Molds continues to grow and expand its operations, the company remains committed to its core values of excellence, innovation, and customer satisfaction. With a focus on delivering superior products and services, Rapid Molds is poised to lead the industry for years to come. Businesses in need of top-quality molds and reliable production processes can trust Rapid Molds to deliver the solutions they need to succeed.

Top Sheet Metal Prototypes Service in China

China Sheet Metal Prototypes Service Empowers Manufacturing Industry with Advanced Technologies and Precision EngineeringIn the competitive manufacturing industry, the demand for high-quality sheet metal prototypes has been at an all-time high. With the increasing complexity of product designs and the need for quick turnaround times, manufacturers are constantly seeking reliable and efficient sheet metal prototyping services to meet their production needs.One company that has been leading the way in providing top-notch sheet metal prototyping services is {}. With a solid reputation for delivering precision engineering solutions and advanced technologies, they have been empowering the manufacturing industry with high-quality prototypes that exceed client expectations.{} utilizes state-of-the-art equipment and cutting-edge technologies to produce sheet metal prototypes with unmatched precision and quality. The company's team of skilled engineers and technicians are well-versed in the latest industry standards and best practices, ensuring that every prototype meets the highest quality standards.The company's advanced capabilities in sheet metal prototyping allow them to cater to a wide range of industries, including automotive, aerospace, electronics, and more. By leveraging their expertise in precision engineering and manufacturing, they are able to address the unique requirements of each industry and deliver tailor-made solutions that optimize production processes and streamline manufacturing operations.One of the key factors that sets {} apart from other sheet metal prototyping services is their commitment to customer satisfaction. The company prioritizes open communication and collaboration with clients throughout the prototyping process, ensuring that their unique requirements and specifications are met. This customer-centric approach has earned them a loyal and satisfied client base, further solidifying their position as a trusted leader in the industry.In addition to their technical expertise, {} also places a strong emphasis on sustainability and environmental responsibility. The company is dedicated to adopting eco-friendly practices and materials in their prototyping processes, minimizing waste and reducing their carbon footprint. By integrating sustainable practices into their operations, they are not only contributing to a greener future but also helping their clients meet their own sustainability goals.With an unwavering commitment to excellence, {} continues to push the boundaries of sheet metal prototyping, delivering innovative solutions that drive the manufacturing industry forward. Their focus on continuous improvement and investment in cutting-edge technologies positions them at the forefront of the industry, allowing them to stay ahead of the curve and meet the evolving needs of their clients.Looking ahead, {} remains dedicated to further enhancing their capabilities and expanding their offerings to better serve the manufacturing industry. Their relentless pursuit of excellence and unwavering dedication to customer satisfaction make them a go-to partner for manufacturers seeking high-quality sheet metal prototypes that meet the highest standards of precision and reliability.In conclusion, the manufacturing industry's growing demand for high-quality sheet metal prototypes has propelled companies like {} to the forefront of the industry. With their advanced technologies, precision engineering, and customer-centric approach, they continue to empower manufacturers with innovative solutions that drive efficiency, elevate production processes, and set new standards for quality in sheet metal prototyping. As the industry continues to evolve, {} remains committed to pushing the boundaries of what's possible and delivering exceptional results that exceed client expectations.

Low Volume Plastic Injection Molding Products in China

Manufacturing of low volume plastic injection molding products has seen a surge in demand in recent years, especially in the market of China. With the increasing need for customized and small-scale production, the industry has witnessed significant growth and development. One company that has been at the forefront of this trend is {}. {} is a leading manufacturer and supplier of low volume plastic injection molding products in China. With a strong focus on quality, precision, and customer satisfaction, the company has carved a niche for itself in the highly competitive market. The company specializes in providing custom plastic injection molding solutions for a wide range of industries, including automotive, electronics, medical devices, consumer goods, and more.One of the key factors that set {} apart from its competitors is its state-of-the-art manufacturing facility equipped with advanced technology and machinery. The company utilizes the latest injection molding techniques and processes to ensure that each product meets the highest standards of quality and durability. With a dedicated team of experienced engineers and technicians, {} is able to offer a wide range of services, including product design, rapid prototyping, mold making, and production of low volume plastic parts.In addition to its technical capabilities, {} places a strong emphasis on customer satisfaction and communication. The company works closely with clients to understand their specific requirements and deliver customized solutions that meet their needs. Whether it's a complex design or a small-scale production run, {} is committed to providing the highest level of service and support to its customers.With the increasing demand for low volume plastic injection molding products, {} has continued to expand its capabilities and capacity to meet the growing needs of its clients. The company has invested in new machinery, technology, and training to ensure that it remains at the forefront of the industry. As a result, {} has been able to maintain its reputation as a reliable and trusted partner for businesses looking for high-quality plastic injection molding solutions.Looking ahead, {} is poised for further growth and success in the industry. The company is constantly exploring new opportunities and markets to expand its reach and serve a wider range of clients. With a strong commitment to innovation, quality, and customer satisfaction, {} is well-positioned to continue driving the growth of the low volume plastic injection molding industry in China and beyond.In conclusion, the demand for low volume plastic injection molding products continues to rise, and companies like {} are playing a crucial role in meeting this demand. With its advanced manufacturing capabilities, commitment to quality, and customer-centric approach, {} has established itself as a leading provider of custom plastic injection molding solutions. As the industry continues to evolve, {} remains dedicated to driving innovation and delivering excellence in every aspect of its operations.

Top Metal Stamping Equipment for Precision Manufacturing

Metal stamping equipment from {} is revolutionizing the manufacturing industry with its cutting-edge technology and superior quality products. With a commitment to innovation and customer satisfaction, {} has established itself as a leader in the metal stamping equipment industry.{} is a renowned manufacturer of metal stamping equipment, offering a wide range of products that cater to various industrial needs. The company's dedication to research and development has led to the creation of high-performance equipment that is unmatched in the market. With a focus on precision, efficiency, and reliability, {}'s metal stamping equipment is trusted by manufacturers across the globe.The key to {}'s success lies in its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. The company's production line is equipped with the latest technology and machinery, allowing for the efficient and cost-effective manufacturing of metal stamping equipment. From design to assembly, {} ensures that each product meets the highest standards of quality and performance.One of the standout features of {}'s metal stamping equipment is its versatility. The company offers a wide range of products, including mechanical and hydraulic presses, coil handling equipment, and automation solutions. This diverse product line caters to the needs of various industries, including automotive, aerospace, electronics, and construction. Whether it's a small-scale operation or a large manufacturing facility, {} has the perfect metal stamping equipment to meet any production requirement.In addition to its impressive product range, {} prides itself on its commitment to customer satisfaction. The company's team of experts works closely with clients to understand their specific needs and provide tailored solutions that maximize efficiency and productivity. {}'s dedication to customer service has earned it a loyal customer base and a reputation for excellence in the industry.Furthermore, {} is dedicated to sustainability and environmental responsibility. The company implements eco-friendly practices in its manufacturing processes, ensuring minimal waste and energy consumption. By prioritizing sustainability, {} not only contributes to a greener planet but also helps its clients meet their own sustainability goals.With a strong focus on innovation and continuous improvement, {} is constantly pushing the boundaries of metal stamping technology. The company invests heavily in research and development, staying ahead of industry trends and technological advancements. This dedication to innovation ensures that {}'s metal stamping equipment remains at the forefront of the industry, providing clients with cutting-edge solutions that drive their businesses forward.As a testament to its success and industry leadership, {} has received numerous accolades and certifications for its metal stamping equipment. The company's commitment to quality and excellence has been recognized by industry bodies and regulatory authorities, further solidifying its position as a trusted manufacturer of metal stamping equipment.In conclusion, {} is a powerhouse in the metal stamping equipment industry, known for its innovation, quality, and customer-centric approach. With a diverse product line, a dedication to sustainability, and a relentless pursuit of excellence, {} is set to continue its reign as a leader in the manufacturing industry. Clients can trust {} to provide them with the best metal stamping equipment for their production needs, backed by a team of experts committed to their success.

Rapid Prototyping Definition: What You Need to Know about OEM Suppliers

OEM Rapid Prototyping Definition Supplier, a leading provider of rapid prototyping solutions, is dedicated to delivering high-quality services and products that enable businesses to bring their innovative ideas to life. With years of experience in the industry, they have established themselves as a trusted partner for companies looking to quickly and cost-effectively develop prototypes and bring their products to market.As a rapid prototyping definition supplier, OEM understands the importance of quickly turning ideas into tangible prototypes. They offer a wide range of rapid prototyping services, including 3D printing, CNC machining, and injection molding. Their state-of-the-art manufacturing facilities and experienced team of engineers allow them to provide fast turnaround times and high-quality prototypes to their clients.One of the key benefits of working with OEM is their ability to handle complex designs and produce prototypes with precision and accuracy. Their advanced machinery and advanced manufacturing processes enable them to create intricate and detailed prototypes that meet the specific requirements of their clients. Whether it's a small-scale prototype or a large, complex model, OEM has the capabilities to deliver top-notch results.In addition to their rapid prototyping services, OEM also provides comprehensive design and engineering support to help clients optimize their designs for manufacturing. This collaborative approach ensures that prototypes are not only functional and accurate but also designed for easy production and assembly. By partnering with OEM, businesses can streamline their product development process and reduce the time and cost of bringing a new product to market.Furthermore, OEM is committed to quality and customer satisfaction, offering stringent quality control measures and rigorous testing procedures to ensure that every prototype meets the highest standards. This dedication to excellence has earned them a reputation as a reliable and trusted partner for businesses across various industries.To further support their clients, OEM also offers flexible and customizable solutions tailored to the unique needs of each project. Whether it's a one-off prototype or a large-scale production run, their team works closely with clients to understand their requirements and deliver a solution that meets their specific needs.Overall, OEM Rapid Prototyping Definition Supplier is dedicated to providing businesses with the tools and resources they need to bring their ideas to life. From rapid prototyping services to design and engineering support, they offer a comprehensive range of solutions to help companies innovate and succeed in today's competitive market.Company Introduction:Founded in [year], OEM Rapid Prototyping Definition Supplier has quickly emerged as a leader in the rapid prototyping industry. With a focus on delivering high-quality prototypes and exceptional customer service, they have built a strong reputation for excellence and reliability.Their team consists of experienced engineers, designers, and manufacturing experts who are passionate about helping clients bring their ideas to life. They are committed to staying ahead of the curve in terms of technology and industry trends, ensuring that they can provide the most advanced and innovative prototyping solutions to their clients.With a customer-centric approach, OEM strives to build long-term partnerships with businesses across various industries, from automotive and aerospace to consumer electronics and medical devices. They understand the unique challenges and requirements of each industry and work closely with clients to deliver solutions that meet their specific needs.In addition to their commitment to quality and innovation, OEM also places a strong emphasis on sustainability and environmental responsibility. They continuously invest in environmentally friendly manufacturing processes and materials, ensuring that their prototyping solutions are not only efficient and cost-effective but also eco-friendly.As they continue to grow and expand their capabilities, OEM Rapid Prototyping Definition Supplier remains dedicated to helping businesses innovate and succeed in today's fast-paced market. With their comprehensive range of rapid prototyping services and their unwavering commitment to excellence, they are well-positioned to continue driving innovation and empowering businesses to turn their ideas into reality.