| Surfece Finishes | Description | Material | Colour | Texture |

| Anodized | Improving corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface | Aluminum | Silver, Black, Red, Blue | Matte and Smooth Finish |

| Bead blasting (Sandblasting ) | Matte surface for viable application for other surface finish like anodized, painting etc | Aluminum, steel, SS, Brass, Plastic | N/A | Matte Surface |

| Painting | Wet painting or Powder coat | Aluminum, steel, SS, Plastic | Any RAL OR Pantone colors | Matte and Glossy Finish |

| Polishing | Polishing is a process to improve machined surface, creating a smooth and glossy surface | Any Metal, Any Plastic | N/A | Smooth and Glossy |

| Brushing | Using abrasive belt to draw traces on surface | Aluminum, steel, SS, Brass | N/A | Stain |

| Electroplating | Electroplating is decorative or corrosion related | Aluminum, steel, SS | N/A | Glossy Surface |

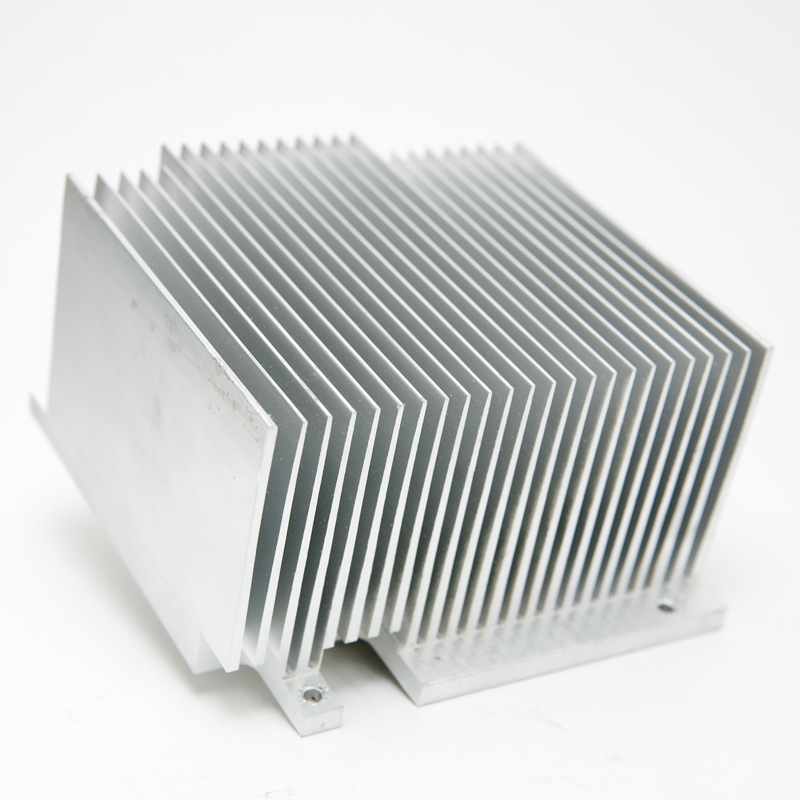

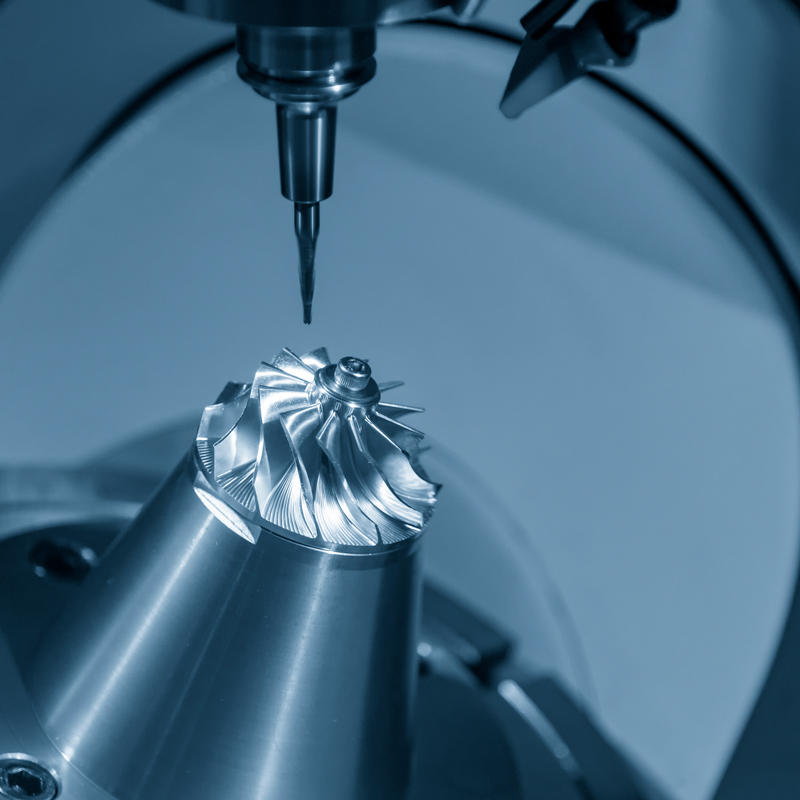

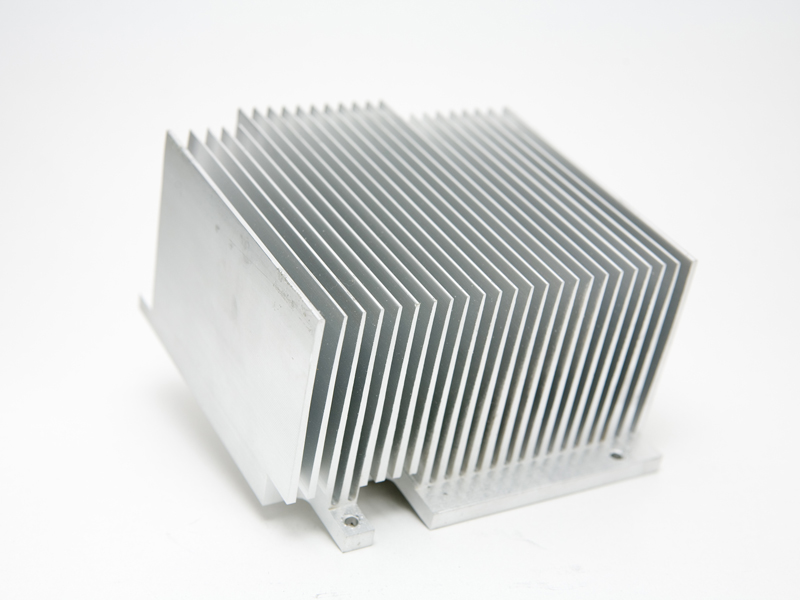

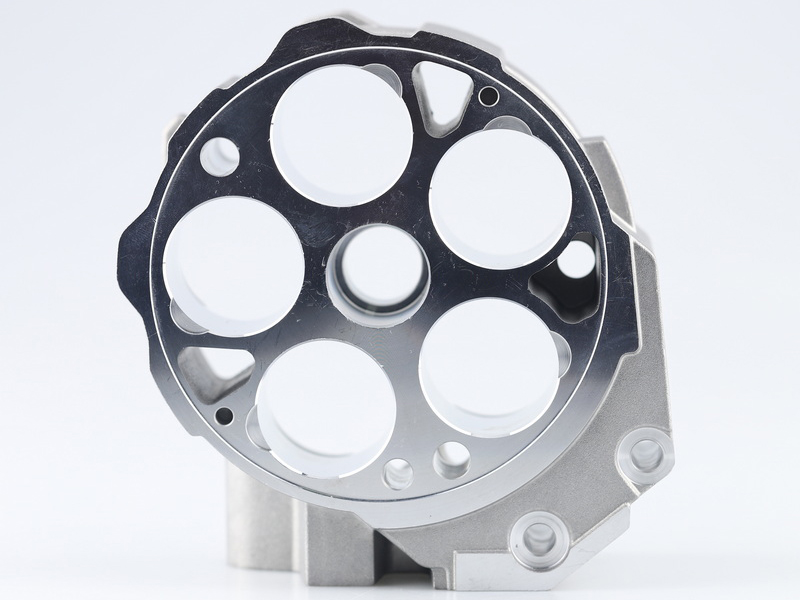

Full Capacity: by combining other technique such as wire cut , EDM etc , ,Foxstar not only machine simple parts but also machine complex part with high tolerance. Quick turnaround: Dealing with inquiry in 8-12 hours, to save time, any design improvement ideas will be provided with the quote. 7/24 hours sales supports could response your request. Professional Engineering Team: Experienced engineer provide the best CNC machine solution, material suggestion and surface finish option. High Quality: Full inspection prior to shipping, to guarantee you will receive qualified machined parts. At Foxstar, we're more than a CNC machining service; we're your reliable partner to make your idea into real sharp. Choose us and choose the best. Your project deserves it.For engineers, product developers, and designers requiring from prototyping to low-volume production, Foxstar's custom CNC services is the best choice. From simple to complicated designs with tight tolerances, our ISO 9001 certified CNC machine shops ensure the highest quality . We provide cnc milling service and cnc turning service .CNC milling is a highly adaptable machining method capable of multi-axis operations, including 3 ,4 and 5 axes. Offer precision and allow for the creation of detailed and specific geometries from metal or plastic blocks.

Full Capacity: by combining other technique such as wire cut , EDM etc , ,Foxstar not only machine simple parts but also machine complex part with high tolerance. Quick turnaround: Dealing with inquiry in 8-12 hours, to save time, any design improvement ideas will be provided with the quote. 7/24 hours sales supports could response your request. Professional Engineering Team: Experienced engineer provide the best CNC machine solution, material suggestion and surface finish option. High Quality: Full inspection prior to shipping, to guarantee you will receive qualified machined parts. At Foxstar, we're more than a CNC machining service; we're your reliable partner to make your idea into real sharp. Choose us and choose the best. Your project deserves it.For engineers, product developers, and designers requiring from prototyping to low-volume production, Foxstar's custom CNC services is the best choice. From simple to complicated designs with tight tolerances, our ISO 9001 certified CNC machine shops ensure the highest quality . We provide cnc milling service and cnc turning service .CNC milling is a highly adaptable machining method capable of multi-axis operations, including 3 ,4 and 5 axes. Offer precision and allow for the creation of detailed and specific geometries from metal or plastic blocks. CNC turning employs CNC lathes and turning centers to shape metal rod stock, primarily focusing on creating cylindrical parts. This process ensures that components meet precise dimensions consistently and achieve smooth finishes.

CNC turning employs CNC lathes and turning centers to shape metal rod stock, primarily focusing on creating cylindrical parts. This process ensures that components meet precise dimensions consistently and achieve smooth finishes. LEARN MORELEARN MORE

LEARN MORELEARN MOREStart with a prototype, progress to small batches, and culminate in precise parts tailored for your project. Each solution is crafted to meet your requirements.

Transform your concepts into tangible products swiftly through Rapid Prototyping. Identify and rectify design flaws in the initial stages, thereby reducing time and expenses, all while guaranteeing that your CNC machined item is ready for the market.Require a small quantity production without the delay? Our Low-volume Production swiftly delivers machined components, bypassing the necessity for extensive orders, striking a balance between expenses and effectiveness.Gain adaptability for orders of any size through our On-Demand Production, liberating customers from limitations on volume while ensuring precision and quality in CNC machining