Get Quotes for Sheet Metal Prototypes - Compare OEM Options

By:Admin

The ability to obtain OEM sheet metal prototypes quotes is a significant advancement for Foxstar's clients. With this new service, clients can now easily obtain accurate quotes for their sheet metal prototype projects. This will allow them to better plan and budget for their manufacturing needs, ensuring a smooth and efficient production process.

Foxstar's commitment to superior precision and efficiency is evident in all of its manufacturing services. Whether clients require CNC machining, injection molding, 3D printing, or sheet metal fabrication, Foxstar has the expertise and technology to deliver high-quality results. The company's team of skilled engineers and technicians work closely with clients to understand their specific requirements and provide custom solutions that meet their needs.

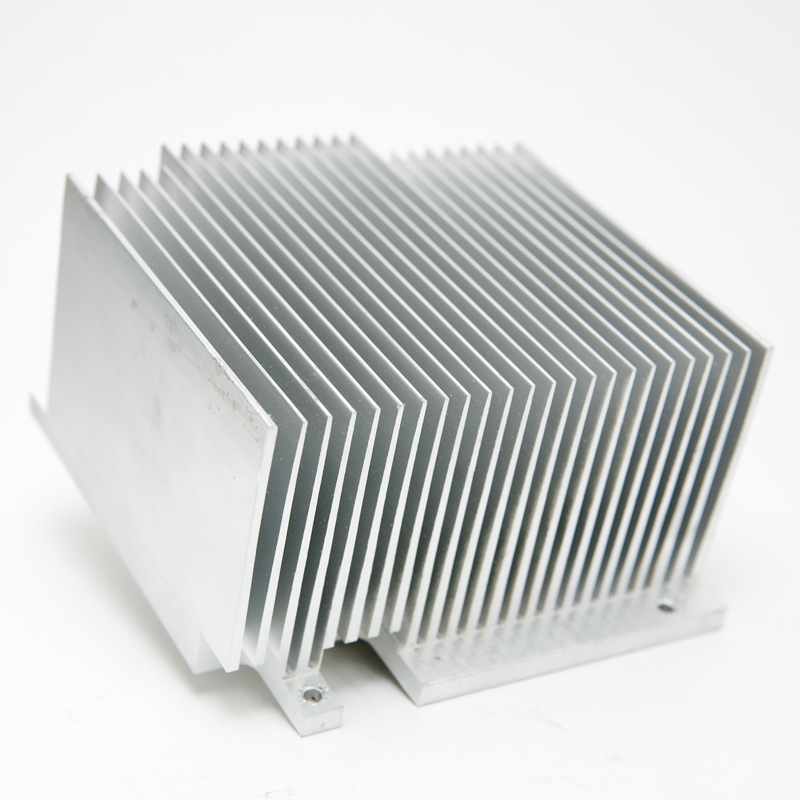

In addition to offering OEM sheet metal prototypes quotes, Foxstar also offers a wide range of materials and finish options for its sheet metal fabrication services. Clients can choose from various metals, including aluminum, steel, and stainless steel, as well as a variety of finish options, such as powder coating, anodizing, and plating. This flexibility allows clients to achieve the specific look and performance they desire for their sheet metal prototypes.

Furthermore, Foxstar's one-stop solutions for manufacturing needs streamline the production process for clients. With the ability to provide a wide range of manufacturing services under one roof, clients can benefit from improved efficiency and cost savings. Instead of working with multiple vendors for different manufacturing processes, clients can rely on Foxstar to handle all aspects of their project, from initial design to final production.

Foxstar's dedication to providing superior precision and efficiency has made it a trusted partner for clients in a wide range of industries. From automotive and aerospace to consumer electronics and medical devices, Foxstar has the expertise and resources to meet the unique needs of each industry. The company's commitment to quality and innovation has earned it a reputation as a leading manufacturing company in the industry.

With the introduction of OEM sheet metal prototypes quotes, Foxstar continues to demonstrate its commitment to meeting the evolving needs of its clients. By providing accurate and timely quotes for sheet metal prototypes, the company is empowering its clients to make informed decisions and plan for successful manufacturing projects. This new service further solidifies Foxstar's position as a go-to partner for all manufacturing needs.

Overall, Foxstar's dedication to delivering superior precision and efficiency, combined with its wide range of manufacturing services and one-stop solutions, makes it a valuable partner for clients across industries. The introduction of OEM sheet metal prototypes quotes is just one example of how the company is continuously striving to meet and exceed the needs of its clients. With a focus on quality, innovation, and customer satisfaction, Foxstar is poised to continue its success as a leading manufacturing company in the industry.

Company News & Blog

Top 5 Lathes Machine Features You Need to Know

Precision and Efficiency: The Versatility of Lathes Machine in Modern ManufacturingIn the world of manufacturing, precision and efficiency are paramount. Companies are constantly seeking the latest technology and tools to deliver high-quality products to their clients. One such tool that has revolutionized the manufacturing industry is the lathe machine. Combined with the diverse capabilities of a company like Foxstar, which offers CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, these machines are providing one-stop solutions for manufacturing needs.A lathe machine is a versatile tool used to shape, cut, and even deform materials such as metal, wood, and plastic. It works by rotating the material on its axis and using cutting tools to create the desired shape. Lathes have been a staple in manufacturing for centuries, and with advancements in technology, they have become even more essential in modern manufacturing processes.The precision and efficiency of lathe machines have made them indispensable in the production of a wide range of products across various industries. From automotive parts to medical devices, and from aerospace components to consumer goods, the applications of lathe machines are virtually limitless.At Foxstar, the use of lathe machines is just one of the many ways the company delivers superior precision and efficiency on every project. With a focus on serving multiple industries and offering a variety of materials and finish options, Foxstar has become a leader in providing high-quality manufacturing solutions.One of the key strengths of lathe machines is their ability to produce intricate and complex shapes with exceptional accuracy. This makes them ideal for creating prototypes, custom parts, and components that require tight tolerances. The precision of these machines allows Foxstar to meet the exact specifications of their clients, ensuring that each product is manufactured to the highest standards.Additionally, lathe machines are known for their efficiency in producing large volumes of parts with consistent quality. This is particularly important in industries where mass production is required, such as automotive manufacturing and electronics production. Foxstar has leveraged the capabilities of lathe machines to meet the demands of their clients, delivering high-quality products in a timely manner.The versatility of lathe machines is further enhanced by the wide range of materials that can be machined. From traditional metals like aluminum, steel, and titanium, to modern composites and plastics, these machines can handle a variety of materials with ease. This flexibility enables Foxstar to offer comprehensive manufacturing solutions to their clients, regardless of the material requirements.In addition to their standalone capabilities, lathe machines can also be integrated with other manufacturing processes to create more complex and sophisticated products. This integration allows Foxstar to offer a complete suite of manufacturing services, from design and prototyping to full-scale production and assembly.Furthermore, the use of lathe machines at Foxstar is complemented by advanced CNC machining, injection molding, sheet metal fabrication, and 3D printing capabilities. This combination of technologies not only enhances the versatility of the company's manufacturing processes, but also allows them to cater to a wide range of industries and applications.The commitment to delivering superior precision and efficiency on every project is at the core of Foxstar's mission. By leveraging the capabilities of lathe machines and other advanced manufacturing technologies, the company has established itself as a reliable partner for businesses seeking high-quality manufacturing solutions.As the manufacturing industry continues to evolve, the role of lathe machines in delivering precision and efficiency will only become more significant. With companies like Foxstar leading the way, the future of manufacturing looks promising, with innovative products and solutions that meet the demands of the modern market.In conclusion, the versatility of lathe machines, combined with the comprehensive manufacturing capabilities of companies like Foxstar, has transformed the way products are made. With a focus on precision, efficiency, and a commitment to meeting the diverse needs of their clients, Foxstar is at the forefront of modern manufacturing. As the industry continues to evolve, the role of lathe machines will undoubtedly remain essential in delivering high-quality products that meet the highest standards.

Small Batch Casting Quotes for OEM Products

Today, the small batch casting industry has seen a significant shift in demand as more companies are looking for high-quality, custom parts for their products. One company that has been at the forefront of this change is {}, a leading supplier of OEM small batch casting services.In a recent statement, a representative from {} stated, "We have seen a noticeable increase in the number of companies looking for small batch casting quotes. This trend is indicative of the growing preference for custom, high-quality parts that meet specific design and performance requirements."{} has been a key player in the small batch casting industry for many years, offering a wide range of casting services to meet the diverse needs of its clients. With a focus on precision and quality, the company has built a reputation for delivering exceptional casting solutions for a variety of industries, including automotive, aerospace, and consumer goods.The company's state-of-the-art facilities and advanced manufacturing capabilities have allowed {} to consistently meet the demands of its clients, delivering small batch casting solutions that are both cost-effective and of the highest quality. By leveraging the latest casting technologies and processes, the company is able to produce complex, custom parts with tight tolerances and superior surface finishes.In addition to its manufacturing capabilities, {} is also known for its dedication to customer service and support. The company works closely with its clients throughout the entire casting process, from initial design and prototyping to final production and delivery. This collaborative approach ensures that clients receive the precise parts they need, on time and within budget.One of the key factors driving the increased demand for small batch casting quotes is the growing emphasis on customization and innovation in product development. As companies strive to differentiate their products in the market, the need for custom, high-quality parts has become more pronounced. {} has positioned itself as a trusted partner for companies seeking to bring their unique designs to life through small batch casting.In response to the rising demand for small batch casting quotes, {} has expanded its capabilities and capacity to accommodate the needs of its clients. The company has invested in new technologies and equipment, allowing it to take on a wider range of casting projects while maintaining its commitment to quality and precision.The company's dedication to innovation and excellence has earned it a loyal customer base and a strong reputation in the small batch casting industry. As more companies recognize the value of custom, high-quality parts, {} is poised to continue leading the way in providing top-notch casting solutions for a wide range of applications.In conclusion, the increasing demand for small batch casting quotes is a reflection of the shift towards customization and precision in product development. As companies seek to create unique, high-quality products, the need for custom casting solutions has become more prevalent. With its advanced capabilities and unwavering commitment to quality, {} is well-positioned to meet this demand and continue to drive innovation in the small batch casting industry.

Top Ways to 3D Print Quickly and Efficiently

Foxstar Introduces Quick 3D Printing Solution for Superior Precision and EfficiencyIn today's fast-paced manufacturing world, companies are constantly seeking innovative solutions to streamline their production processes and deliver high-quality products in a timely manner. Foxstar, a leading manufacturing company, is at the forefront of this effort with their latest offering - Quick 3D Printing. This cutting-edge technology, combined with the company's extensive range of manufacturing services, is set to revolutionize the industry and provide customers with superior precision and efficiency on every project.With a firm commitment to delivering excellence in manufacturing, Foxstar has established a reputation for providing a wide range of services including CNC machining, injection molding, and sheet metal fabrication. Their expertise extends to 3D printing, where they offer a variety of materials and finish options to meet the unique needs of their clients. This one-stop solution approach has enabled Foxstar to cater to multiple industries, including automotive, aerospace, consumer electronics, and more.The introduction of Quick 3D Printing underscores Foxstar's dedication to staying ahead of the curve and adapting to the evolving needs of the industry. This advanced technology allows for rapid prototyping and production of complex parts with intricate designs, all while maintaining the highest levels of precision and quality. With Quick 3D Printing, customers can expect faster turnaround times and reduced lead times, ultimately leading to cost savings and increased productivity.One of the key advantages of Quick 3D Printing is its ability to produce highly detailed and functional prototypes in a matter of hours, as opposed to traditional manufacturing methods which often require days or weeks. This accelerated turnaround time not only allows for faster product development and testing but also enables companies to bring their ideas to market quicker than ever before. In addition, Quick 3D Printing offers a level of flexibility that is unmatched, allowing for on-the-fly design modifications and iterations with minimal impact on production schedules.Furthermore, Foxstar's Quick 3D Printing service is backed by their team of skilled engineers and technicians who possess the expertise to guide clients through the entire process, from design to production. This collaborative approach ensures that each project is executed with precision and efficiency, ultimately leading to the successful realization of their customers' visions.The versatility of Quick 3D Printing also extends to its compatibility with a wide range of materials, including plastics, resins, and even metal alloys. This flexibility allows for the production of parts with varying properties and characteristics, making it suitable for a wide array of applications across different industries. Additionally, Foxstar's state-of-the-art facilities are equipped with the latest 3D printing technology, ensuring that clients receive the highest standard of quality and consistency in every part produced.As companies continue to navigate the demands of an increasingly competitive market, having access to advanced manufacturing solutions such as Quick 3D Printing is essential for staying ahead of the curve. Foxstar's commitment to delivering superior precision and efficiency through their Quick 3D Printing service demonstrates their unwavering dedication to innovation and customer satisfaction. With this latest offering, they are poised to set new benchmarks in the industry and empower their clients to bring their ideas to life with unprecedented speed and precision.

Quality Prototype Molds: The Key to Successful Product Development

Foxstar, a leading manufacturing company, is revolutionizing the industry with its state-of-the-art prototype molds. The company, known for delivering superior precision and efficiency on every project, offers a wide range of manufacturing services including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more. With a strong focus on providing one-stop solutions for manufacturing needs, Foxstar is catering to multiple industries with a variety of materials and finish options.Prototype molds are an essential part of the manufacturing process as they allow companies to test and refine their product designs before mass production. Foxstar has distinguished itself in the market by offering high-quality prototype molds that are tailored to meet the specific requirements of its clients.One of the key advantages of choosing Foxstar for prototype molds is the company's advanced CNC machining capabilities. This cutting-edge technology enables Foxstar to produce precise and intricate molds with unparalleled accuracy. By leveraging CNC machining, Foxstar is able to deliver prototype molds that meet the highest quality standards, ensuring that clients can test their designs with confidence.In addition to CNC machining, Foxstar's expertise in injection molding further sets it apart as a leader in the industry. Injection molding is a highly efficient manufacturing process that allows for the production of large quantities of identical parts with minimal waste. With Foxstar's injection molding services, clients can benefit from fast turnaround times and cost-effective solutions for their prototype mold needs.Furthermore, Foxstar's sheet metal fabrication capabilities provide clients with the flexibility to create custom molds that meet their unique specifications. Whether clients require complex geometries or specific material properties, Foxstar's sheet metal fabrication services enable them to achieve their desired outcomes with precision and reliability.Another standout offering from Foxstar is its 3D printing services, which allow clients to rapidly prototype their designs and iterate on them as needed. 3D printing is particularly beneficial for creating intricate and complex molds that may be challenging to produce using traditional manufacturing methods. With Foxstar's 3D printing expertise, clients can explore a wide range of design possibilities and refine their prototypes before advancing to mass production.By combining these diverse manufacturing capabilities, Foxstar is able to provide comprehensive solutions for a wide range of industries, including automotive, aerospace, consumer electronics, and more. Whether clients are seeking prototype molds for new product development or custom tooling for existing projects, Foxstar's versatile services can accommodate their needs with precision and efficiency.Furthermore, Foxstar's commitment to quality extends beyond its manufacturing capabilities. The company places a strong emphasis on providing exceptional customer service, ensuring that clients receive the support and guidance they need throughout the prototyping process. From initial design consultation to final product delivery, Foxstar's team of experts works closely with clients to ensure that their expectations are met and exceeded.As Foxstar continues to expand its presence in the manufacturing industry, the company remains dedicated to pushing the boundaries of innovation and excellence. With a focus on delivering superior prototype molds and manufacturing solutions, Foxstar is well-positioned to meet the evolving needs of its clients and drive the industry forward.In conclusion, Foxstar's comprehensive range of manufacturing services, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, positions the company as a leader in delivering prototype molds of the highest quality. With a steadfast commitment to precision and efficiency, Foxstar is empowering clients across multiple industries to bring their product designs to life with confidence and reliability. As the demand for advanced prototype molds continues to grow, Foxstar stands ready to meet the needs of its clients and exceed their expectations at every turn.

Custom Steel CNC Machining Services: A Complete Guide

Foxstar Introduces Steel CNC Machining Services to Expand Manufacturing CapabilitiesFoxstar is excited to announce the addition of steel CNC machining services to their already impressive portfolio of manufacturing capabilities. This advancement allows Foxstar to further assist their clients by offering even more options for precision and efficiency in their manufacturing projects.Established as a one-stop solution for manufacturing needs, Foxstar has built a reputation for delivering superior quality and expertise in services ranging from CNC machining and injection molding to sheet metal fabrication and 3D printing. By adding steel CNC machining to their arsenal, Foxstar is now better equipped than ever to serve multiple industries with a variety of materials and finish options.CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece, producing a custom-designed part or product. The addition of steel CNC machining to Foxstar's capabilities means that they can now efficiently and precisely manufacture parts from a wide range of steel materials, opening up new possibilities for their clients in industries such as automotive, aerospace, electronics, and more.The introduction of steel CNC machining services is a strategic move for Foxstar, as it allows them to meet the growing demand for high-quality steel components in various industries. With their advanced technology and skilled team of professionals, Foxstar is well-positioned to provide cost-effective and reliable steel CNC machining solutions to their clients."We are thrilled to introduce steel CNC machining services to our offerings," said a spokesperson for Foxstar. "This expansion of our capabilities is a testament to our commitment to providing comprehensive manufacturing solutions to our clients. With the addition of steel CNC machining, we are able to enhance the precision and efficiency of our services, further solidifying our position as a trusted partner for all manufacturing needs."The steel CNC machining services offered by Foxstar are backed by their dedication to meeting and exceeding their clients' expectations. With a focus on delivering top-quality results and outstanding customer service, Foxstar ensures that every project, whether large or small, is executed with the highest level of craftsmanship and attention to detail.The addition of steel CNC machining to Foxstar's repertoire is expected to streamline the production process for their clients, offering a more efficient and cost-effective solution for manufacturing steel components. With their state-of-the-art equipment and extensive expertise in CNC machining, Foxstar is poised to deliver exceptional results for a wide range of applications, including custom parts, prototypes, and production runs.In conclusion, the introduction of steel CNC machining services by Foxstar represents a significant advancement in their ability to cater to the diverse and evolving needs of the manufacturing industry. By leveraging their expertise and resources, Foxstar is now able to offer an even more comprehensive range of manufacturing solutions, further solidifying their position as a leading provider of precision and efficiency in the manufacturing sector.With their unwavering commitment to excellence and customer satisfaction, Foxstar is poised to make a lasting impact with their steel CNC machining services, empowering their clients to achieve new heights of success in their respective industries.

Top Low Volume Plastic Injection Molding Suppliers for Your Needs

Foxstar Offers High-Quality Low Volume Plastic Injection Molding ServicesIn today's fast-paced and highly competitive manufacturing industry, companies are constantly seeking innovative solutions to meet their production needs. Low volume plastic injection molding is a critical part of the manufacturing process for many industries, and finding a reliable supplier with the capabilities to meet specific requirements is essential. Foxstar, a leading manufacturer offering a wide range of precision manufacturing services, has established itself as a top choice for companies seeking high-quality low volume plastic injection molding.Foxstar is committed to delivering superior precision and efficiency on every project, offering a comprehensive range of manufacturing services. From CNC machining and injection molding to sheet metal fabrication and 3D printing, Foxstar serves multiple industries with a variety of materials and finish options. The company's one-stop solutions for manufacturing needs have made it a trusted partner for companies looking for reliable and high-quality manufacturing services.The low volume plastic injection molding services offered by Foxstar are designed to meet the specific needs of each customer, providing cost-effective solutions for small to medium-sized production runs. With state-of-the-art equipment and a team of experienced professionals, Foxstar is capable of handling complex projects with tight tolerances and strict quality requirements.One of the key advantages of working with Foxstar for low volume plastic injection molding is the company's ability to provide custom solutions tailored to the unique needs of each project. Whether a company requires rapid prototyping, low volume production, or full-scale manufacturing, Foxstar has the expertise and capabilities to deliver high-quality results.Foxstar's commitment to precision and efficiency is demonstrated in its advanced manufacturing processes, which are designed to optimize production and minimize waste. By leveraging the latest technology and industry best practices, Foxstar is able to deliver consistent and reliable results, meeting the demands of today's fast-paced and dynamic manufacturing environment.In addition to its technical capabilities, Foxstar is also known for its unwavering commitment to customer satisfaction. The company's team of experts works closely with each customer to understand their unique requirements and provide personalized support throughout the entire manufacturing process. This customer-centric approach has enabled Foxstar to build long-lasting relationships with a diverse range of clients, from startups to Fortune 500 companies.With a focus on quality, innovation, and flexibility, Foxstar has established itself as a leader in low volume plastic injection molding, providing a competitive edge for companies seeking reliable manufacturing services. By offering a comprehensive range of manufacturing solutions and a dedication to superior customer service, Foxstar continues to set the standard for excellence in the industry.As the demand for low volume plastic injection molding services continues to grow, Foxstar is well-positioned to meet the evolving needs of the manufacturing industry. With a strong track record of delivering high-quality results and a commitment to continuous improvement, Foxstar is poised to remain a top choice for companies seeking innovative and reliable manufacturing solutions.In conclusion, Foxstar's low volume plastic injection molding services offer a compelling combination of precision, efficiency, and flexibility, making it the ideal partner for companies seeking high-quality manufacturing solutions. With a focus on customer satisfaction and a dedication to delivering superior results, Foxstar continues to set the bar for excellence in the industry, providing a competitive advantage for companies looking to streamline their manufacturing processes and achieve their production goals.

Small Batch Casting Service in China: A Comprehensive Guide

Foxstar, a leading small batch casting service provider in China, is revolutionizing the manufacturing industry with its superior precision and efficiency. The company offers a wide range of services, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, catering to multiple industries with a variety of materials and finish options.With a focus on delivering high-quality small batch casting solutions, Foxstar has quickly become a preferred partner for businesses looking for reliable and cost-effective manufacturing services. The company's commitment to excellence and innovation has earned it a reputation as a trusted and dependable source for small batch casting needs.Foxstar's small batch casting service is designed to meet the diverse needs of its clients, offering tailored solutions that help bring their ideas to life. The company's team of skilled technicians and engineers work closely with clients to understand their specific requirements and provide them with the best possible small batch casting solutions to meet their needs.One of the key advantages of Foxstar's small batch casting service is its precision and attention to detail. The company utilizes advanced manufacturing techniques and state-of-the-art equipment to ensure that each casting meets the highest standards of quality and accuracy. This precision is crucial for industries such as aerospace, automotive, and medical, where the smallest imperfection can have serious consequences.In addition to precision, efficiency is another hallmark of Foxstar's small batch casting service. The company understands the importance of meeting deadlines and delivering products on time, which is why it has streamlined its manufacturing processes to minimize lead times and optimize production efficiency. This commitment to efficiency ensures that clients receive their small batch castings in a timely manner, allowing them to stay on schedule and meet their own deadlines.Foxstar's small batch casting service is also known for its versatility. The company has the capability to work with a wide range of materials, including aluminum, steel, and various alloys, allowing it to accommodate the unique needs of different industries. Additionally, Foxstar offers a variety of finish options, such as painting, plating, and anodizing, providing clients with the flexibility to customize their small batch castings to their exact specifications.Furthermore, Foxstar is committed to providing one-stop solutions for all manufacturing needs. In addition to its small batch casting service, the company also offers CNC machining, injection molding, sheet metal fabrication, 3D printing, and more. This comprehensive range of services allows clients to rely on Foxstar for all their manufacturing needs, simplifying the supply chain and ensuring consistent quality across the board.As a leading small batch casting service provider in China, Foxstar is dedicated to staying at the forefront of the industry. The company is continually investing in R&D and adopting the latest technologies to enhance its manufacturing capabilities and stay ahead of the competition. This commitment to innovation ensures that clients receive the most advanced and cutting-edge small batch casting solutions available on the market.In conclusion, Foxstar's small batch casting service is a game-changer for businesses looking for precision, efficiency, and versatility in their manufacturing needs. With a commitment to excellence, a wide range of services, and a relentless focus on innovation, Foxstar is paving the way for the future of small batch casting in China and beyond. Whether clients need small batch castings for aerospace, automotive, medical, or any other industry, they can trust Foxstar to deliver superior quality and performance on every project.

How to Print a 3D Model: A Step-by-Step Guide

Innovative Company Introduces Cutting-Edge 3D Printing TechnologyIn a world where technology continues to advance at an exponential rate, the introduction of 3D printing has revolutionized the way we manufacture and create products. One company at the forefront of this technological advancement is pushing the boundaries of what is possible with their state-of-the-art 3D printing technology.This forward-thinking company has recently unveiled a groundbreaking 3D printing process that has the potential to revolutionize the way products are made. Their cutting-edge technology allows for the creation of highly complex and intricate 3D models with unparalleled precision and detail. This advancement in 3D printing technology has the potential to disrupt traditional manufacturing processes and pave the way for a new era of innovation and creativity.The company's proprietary 3D printing technology is capable of producing highly detailed and accurate models with a level of precision that was previously thought to be impossible. This breakthrough in 3D printing has the potential to transform a wide range of industries, from aerospace and automotive to healthcare and consumer goods.One of the key advantages of this advanced 3D printing technology is its ability to create complex and customizable products with incredible speed and efficiency. This means that companies can now rapidly prototype and produce high-quality products with minimal lead times, significantly reducing time-to-market and overall production costs.The potential applications for this cutting-edge 3D printing technology are virtually limitless. From creating intricate architectural models to producing custom medical implants, the possibilities are endless. The company's innovative approach to 3D printing has the potential to transform the way we think about design and manufacturing, opening up new opportunities for creativity and innovation.In addition to its advanced 3D printing technology, the company has also established itself as a leader in the industry through its dedication to sustainability and environmental responsibility. By using biodegradable and recyclable materials in its 3D printing process, the company is committed to reducing its environmental impact and promoting sustainable manufacturing practices.Furthermore, the company's focus on research and development has led to continuous advancements in 3D printing technology, ensuring that it remains at the forefront of innovation. With a team of talented engineers and designers, the company is constantly pushing the boundaries of what is possible with 3D printing, developing new techniques and materials that further enhance the capabilities of their technology.As the demand for highly customized and intricately designed products continues to grow, the company's advanced 3D printing technology is poised to play a pivotal role in shaping the future of manufacturing. With its commitment to innovation, sustainability, and excellence, this company is well positioned to lead the way in the rapidly evolving world of 3D printing.In conclusion, the introduction of this cutting-edge 3D printing technology has the potential to transform the manufacturing industry and revolutionize the way products are made. With its unparalleled precision, speed, and sustainability, this innovative company is paving the way for a new era of creativity and possibility. As 3D printing technology continues to advance, the company is poised to remain at the forefront of innovation, driving meaningful change and shaping the future of manufacturing.

Innovative 3D Printing Solutions Revolutionizing Manufacturing Processes

Foxstar, a leading manufacturing company, has recently announced the addition of cutting-edge 3D printing solutions to its wide range of services. This latest offering aims to further enhance the company’s ability to deliver superior precision and efficiency on every project, solidifying its position as a one-stop solution for manufacturing needs across multiple industries.With a strong focus on innovation and technology, Foxstar continues to expand its capabilities to meet the evolving needs of its clients. The addition of 3D printing to its already comprehensive suite of services, including CNC machining, injection molding, and sheet metal fabrication, further demonstrates the company's commitment to providing a diverse range of manufacturing solutions.3D printing, also known as additive manufacturing, has rapidly gained popularity in various industries due to its ability to create complex and customized parts with unmatched precision. By embracing this technology, Foxstar is poised to cater to the growing demand for advanced manufacturing techniques, thereby offering its clients the advantage of faster lead times, cost-effective production, and design flexibility.This new offering also allows Foxstar to work with a wide variety of materials and finish options, enabling the company to meet the unique requirements of different industries. Whether it’s prototyping, low-volume production, or creating intricate components, the versatility of 3D printing provides Foxstar with the capability to deliver high-quality parts with intricate geometries and fine details.In addition to enhancing its manufacturing capabilities, Foxstar’s venture into 3D printing also reinforces the company’s commitment to sustainability. Additive manufacturing is known for its minimal material wastage and efficient use of resources, aligning with Foxstar’s dedication to environmentally responsible manufacturing practices.The integration of 3D printing into Foxstar's services underscores the company's determination to stay at the forefront of technological advancements in manufacturing. By leveraging the latest in additive manufacturing technology, Foxstar is well-positioned to provide its clients with innovative solutions that meet the demands of the rapidly changing industrial landscape.Foxstar's decision to invest in 3D printing technology is not only a strategic move to broaden its service offerings but also a testament to its unwavering dedication to delivering exceptional quality and value to its clients. By continuously expanding its capabilities, the company is able to stay ahead of the curve and remain a trusted partner for businesses seeking reliable and comprehensive manufacturing solutions.The introduction of 3D printing capabilities further solidifies Foxstar's position as a leading manufacturing solutions provider, serving a diverse range of industries, including aerospace, automotive, medical, and consumer goods. The company's ability to offer end-to-end manufacturing solutions, from design to production, sets it apart as a versatile and reliable partner for businesses looking to bring their ideas to life.As Foxstar continues to pave the way for advanced manufacturing technologies, the company is poised to set new industry standards for precision, efficiency, and innovation. With the integration of 3D printing, Foxstar is well-equipped to meet the evolving needs of its clients and contribute to the development of cutting-edge products across various sectors.In conclusion, Foxstar’s addition of 3D printing to its range of manufacturing services underscores the company’s commitment to delivering superior solutions across multiple industries. With a focus on precision, efficiency, and innovation, Foxstar continues to set new benchmarks for manufacturing excellence, solidifying its position as a trusted partner for businesses seeking top-quality manufacturing solutions.

Top-Quality Precision Stamping Services for Strong and Durable Products

High-Precision Stamping: The Key to Superior Precision and Efficiency in ManufacturingIn today's fast-paced and competitive manufacturing industry, precision and efficiency are essential for success. That's why companies are constantly seeking innovative solutions to streamline their production processes and deliver high-quality products to their customers. One such solution that is gaining widespread popularity is high-precision stamping, a manufacturing technique that offers unmatched accuracy and efficiency in producing a wide range of metal components.One company that is at the forefront of high-precision stamping is Foxstar, a leading provider of comprehensive manufacturing solutions. With a strong focus on delivering superior precision and efficiency on every project, Foxstar offers a wide range of manufacturing services, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more. This comprehensive approach allows the company to serve multiple industries with a variety of materials and finish options, providing one-stop solutions for all manufacturing needs.High-precision stamping is a particularly valuable technique in the manufacturing process, allowing for the efficient production of complex metal components with incredibly tight tolerances. This is achieved through the use of advanced stamping equipment and techniques that can accurately and consistently form and shape metal materials, resulting in finished products that meet the highest quality standards.One of the key advantages of high-precision stamping is its ability to produce large quantities of parts with minimal material waste. This is achieved through the use of precision dies and tooling, which can be designed to efficiently utilize the raw material and minimize scrap. As a result, high-precision stamping is a cost-effective manufacturing solution that can help companies reduce their production costs while maintaining high quality and consistency in their products.In addition to its cost-effectiveness, high-precision stamping also offers unmatched accuracy and repeatability in the production of metal components. This is particularly important in industries such as aerospace, automotive, and electronics, where the performance and reliability of components are critical. With high-precision stamping, companies can ensure that every part they produce meets the strictest quality standards, leading to improved product performance and customer satisfaction.Furthermore, high-precision stamping allows for the production of complex geometries and intricate designs that would be difficult or impossible to achieve using other manufacturing techniques. This opens up new possibilities for product innovation and differentiation, allowing companies to stay ahead of the competition and meet the evolving needs of their customers.At Foxstar, high-precision stamping is just one of the many advanced manufacturing techniques that the company leverages to deliver exceptional results for its clients. With a team of highly skilled engineers and technicians, Foxstar is able to provide customized manufacturing solutions that meet the unique requirements of each project. From initial design and prototyping to full-scale production, the company works closely with its clients to ensure that every aspect of the manufacturing process is optimized for precision and efficiency.Beyond high-precision stamping, Foxstar's extensive capabilities in CNC machining, injection molding, sheet metal fabrication, and 3D printing allow the company to offer comprehensive manufacturing solutions that encompass a wide range of materials and production volumes. This versatility enables Foxstar to serve a diverse array of industries, from automotive and aerospace to medical devices and consumer electronics, providing a single point of contact for all manufacturing needs.As the manufacturing industry continues to evolve and demand for high-quality, precision-engineered products grows, the importance of high-precision stamping and advanced manufacturing techniques cannot be understated. Companies like Foxstar are leading the way in delivering superior precision and efficiency in manufacturing, driving innovation and progress across a wide range of industries.In conclusion, high-precision stamping is a crucial component of modern manufacturing, offering unparalleled accuracy, efficiency, and versatility in the production of metal components. With companies like Foxstar at the forefront of this technology, the future of manufacturing looks bright, with endless possibilities for product innovation and advancement.